What Is Dynamic Mechanical Analysis (DMA)?

DMA measures the displacement of the material under an applied force (periodic or constant).

Viscoelastic properties such as storage modulus, loss modulus, and tan delta are calculated by measuring the phase lag between the input applied periodic force and the resulting periodic displacement.

Examples of periodic/sinusoidal force include:

- Viscoelastic material properties can be determined by DMA, such as storage and loss modulus, and tan delta.

- Fatigue tests can be performed under continuous cyclic loading.

- Under a controlled temperature range, the glass transition can be determined.

- Oscillatory shear rheology.

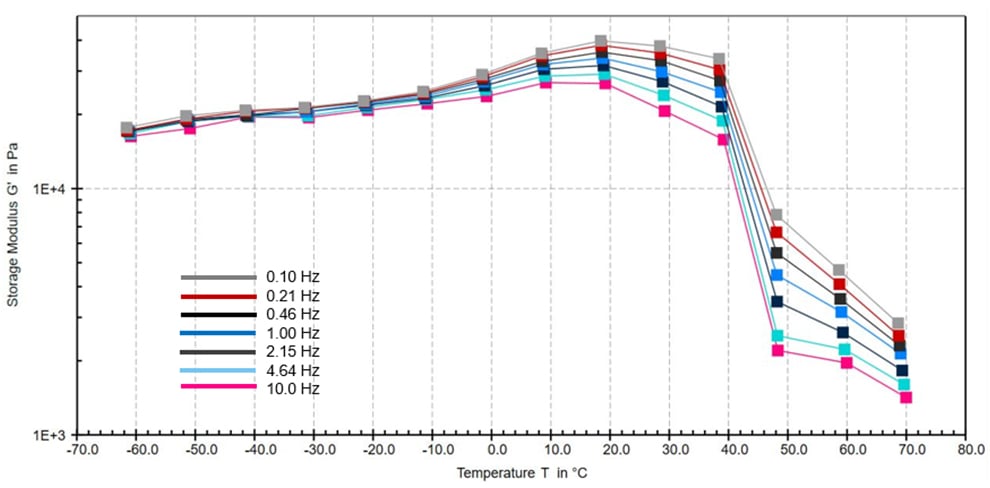

- Time-Temperature Superposition (TTS).

Examples of constant/quasi-static force include:

- Compression-set of elastomers under continual force.

- Creep/recovery.

- Stress vs. strain of soft materials to determine Young’s modulus, ultimate tensile strength, etc.

High Sensitivity

Detect subtle viscoelastic changes, including storage modulus, loss modulus, and tan delta damping analysis.

Thermal Insight

Accurately measure glass transition temperature via DMA, with greater sensitivity than DSC.

Versatile Testing

Supports polymers, gels, and soft metals under tension, torsion, compression, and bending modes.

Why Use DMA?

Dynamic Mechanical Analysis (DMA) is used to measure the bulk mechanical properties of viscoelastic solids, providing precise insights into their behavior under stress. It accommodates solid and gel-phase materials and operates over a typical displacement range from microns to millimeters, with forces ranging from 0.005 N to 50 N. This makes DMA an ideal technique for characterizing the viscoelastic performance of polymers, gels, and other soft materials across various testing conditions.

Polymer Analysis

Enables polymer DMA testing for bulk viscoelastic properties and long-term performance prediction.

Advanced Testing

Provides DMA frequency sweep testing and time–temperature superposition to evaluate material behavior.

Complementary Methods

Works alongside DSC and Instron to deliver complete viscoelastic property testing and reliability insights.

Working Principle

DMA works by applying an oscillatory force or stress to the sample and measuring the sample displacement or strain. Forces can be applied in tension/torsion, compression, and 3-point bend. The phase angle between the stress and strain oscillatory waves is calculated, which allows extrapolation of the storage and loss modulus.

| Mode | Length (mm) | Width (mm) | Thickness (mm) | Temperature range (°C) | Stiffness range (MPa) |

|---|---|---|---|---|---|

| Tension/Torsion | 5 to 35 | 5 to 15 | 0.01-5 | -100-350 | 0.1-10000 |

| Compression | 1 to 40 | 1 to 40 | 0.5-5 | -100-220 | 0.0001-100 |

| 3-pt Bend | 45 to 50 | 10 to 12 | stiff = 0.2-0.3 soft = 1-2 |

-100-350 | 100 to 1000000 |

Force range: 0.005 N to 50 N.

Equipment Used for DMA:

Anton Paar MCR 702 Multidrive (linear and rotation)

The MCR 702 MultiDrive is a combination DMA/rheometer with the flexibility and precision to support a wide range of test modes and configurations.

- Linear Drive (Tension/Bending/Compression mode):

- Maximum Force: 40 N.

- Minimum Force: 0.0005 N (0.5 mN).

- Maximum Displacement: 9,400 µm (9.4 mm).

- Minimum Displacement: 0.01 µm (10 nm).

- Maximum Frequency: 100 Hz.

- Minimum Frequency: 0.001 Hz.

- Temperature Range: −160 °C to +600 °C (with proper temperature control accessory).

- Max Heating Rate: 35 K/min.

- Max Cooling Rate: 30 K/min.

- Rotational Drive (Torsion/Rheology mode):

- Maximum Torque: 230 mNm.

- Minimum Torque (Rotation): 1 nNm.

- Minimum Torque (Oscillation): 0.5 nNm.

- Angular Deflection (Set-value): 0.05 µrad to ∞.

- Angular Velocity Range: approx 10⁻⁹ to 314 rad/s.

- Angular Frequency Range: approx 10⁻⁷ to 628 rad/s.

- Normal Force Range: 0.005 N to 50 N.

- Temperature Range: −160 °C to +1000 °C (depending on accessory).

Key Differentiators

Strengths

- Measures bulk viscoelastic properties such as storage and loss modulus.

- More sensitive measurement of glass transition temperature compared to DSC.

Limitations

- Not ideal for quasi-static tensile tests; the Instron with the 50N load cell is preferred.

- Failure to properly grip or mount the sample during long measurement times can be problematic.

- Coefficient of thermal expansion (CTE) is not well-suited for our tool.

Unsure Whether DMA Is Right for You?

Learn more about using Dynamic Mechanical Analysis testing services today.

Sample Information

What we accept:

DMA requires a solid form of samples of polymers, gels, and soft metals.

Use Cases

Polymers / Plastics / Elastomers

Used to measure glass transition temperature, stiffness, and damping to understand flexibility and performance across temperatures.

Composites & High-Performance Materials

Used to evaluate viscoelastic behavior and service temperature limits for fiber-reinforced and advanced materials.

Adhesives / Coatings / Films

Used to assess cured strength, flexibility, thermal stability, and high‑temperature viscoelastic behavior of adhesives, coatings, thin films, and semiconductor packaging materials (e.g. adhesives, epoxies, thermal interface materials, gels) to characterize flow behavior under load and at operating temperatures above their glass transition temperature (50 °C – 200 °C).

R&D & Quality Control

Used to compare formulations, validate processing, and ensure consistent mechanical and thermal performance.

Biomedical & Soft Materials

Used to characterize the viscoelastic properties and deformation behavior of soft tissues, gels, and biopolymers.

Complementary Techniques

- A universal testing machine like Covalent’s Instron can be used for standardized ASTM tensile tests, such as ASTM D638. This is a complementary technique to DMA for measuring Young’s tensile properties of plastics. Instron can achieve much higher forces compared to DMA (as high as 5kN).

- DSC is a complementary technique to DMA. Both techniques can measure thermal transitions in solid and gel-like materials. DSC is typically recommended as a higher priority test to measure glass transition and melting point. If the glass transition temperature is weak, we would propose following up with DMA. Understanding the melting point also helps us operate DMA within a temperature range that avoids the material from melting during the test.

- Nano-DMA or SINUS mode is an advanced characterization test on the Anton Paar nano-indentation system. While DMA provides bulk viscoelastic property measurements, such as the material’s storage and loss modulus, the SINUS mode measures the surface-level nano-scale viscoelastic properties. SINUS mode is complementary for comparing surface properties with bulk. Examples of complementary technique applications include characterization of thin polymer coatings or targeted locations on a micro-electronic device.

Differential Scanning Calorimetry (DSC)

Quantifies heat flow for material optimization. Explore

Why Choose Covalent for DMA Needs?

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

What properties can DMA measure, other than storage modulus, loss modulus, and tan delta?

DMA can also measure creep, compression-set, and glass transition temperature.

Are liquids suitable for DMA?

Gels are suitable in oscillatory shear mode. However, under linear drive, we require materials to be viscoelastic, meaning they have both viscous and elastic properties.

What sample size and geometry are required for DMA specimens?

Dynamic mechanical analysis (DMA) requires samples in solid form of polymers, gels, and soft metals. The specific specimen dimensions depend on the test mode. Typical ranges are:

- Tension/Torsion: length 5 to 35 mm, width 5 to 15 mm, thickness 0.01 to 5 mm

- Compression: length 1 to 40 mm, width 1 to 40 mm, thickness 0.5 to 5 mm

- 3‑point bend: length 45 to 50 mm, width 10 to 12 mm, thickness 0.2 to 0.3 mm for stiff samples and 1–2 mm for soft samples

What equipment configurations (force, temperature range) does Covalent use for DMA testing?

We typically perform an amplitude sweep at 1 Hz to determine the linear viscoelastic (LVE) range. This is the amplitude range at which the storage modulus is constant. Viscoelastic materials display frequency-dependent properties. If needed, we conduct frequency sweeps at an amplitude in the LVE. All tests are conducted at room temperature unless specified by the customer.

How long does a DMA test typically take? Are there expedited service options?

Tests can range from a few minutes to several hours, depending on the procedure. We understand that some tests are time-dependent. We can accommodate by scheduling same-day testing with one week’s advance notice.