What Is X-ray Diffraction (XRD)?

X-ray Diffraction (XRD) is a non-destructive scattering technique that measures how X-rays diffract through a crystal lattice. The resulting patterns reveal information about the phases, structures, and textures of crystalline materials.

Lattice Measurement

Explains crystal symmetry and spacing using constructive interference (Bragg’s Law).

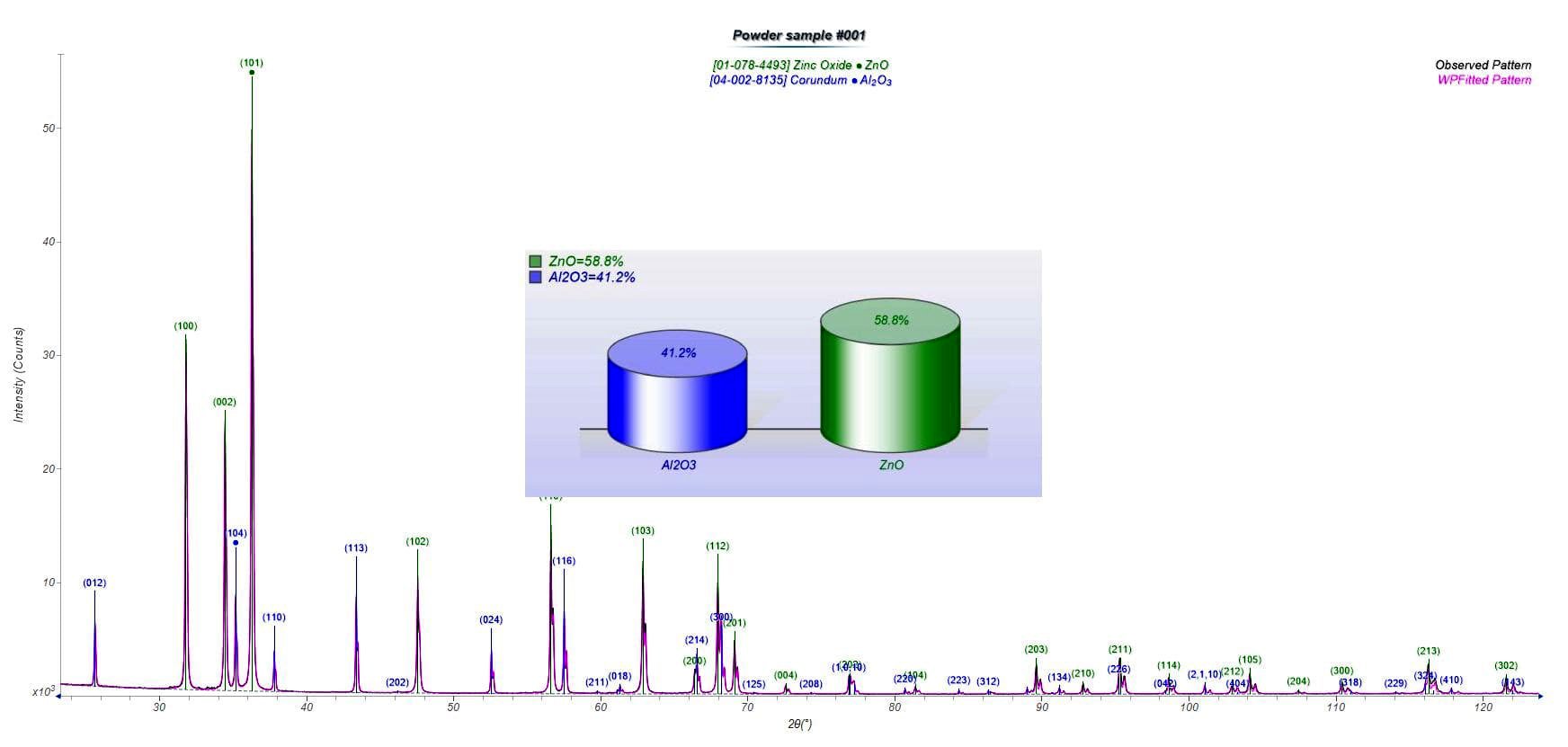

Phase Fingerprinting

Generates characteristic diffraction patterns unique to each crystalline material.

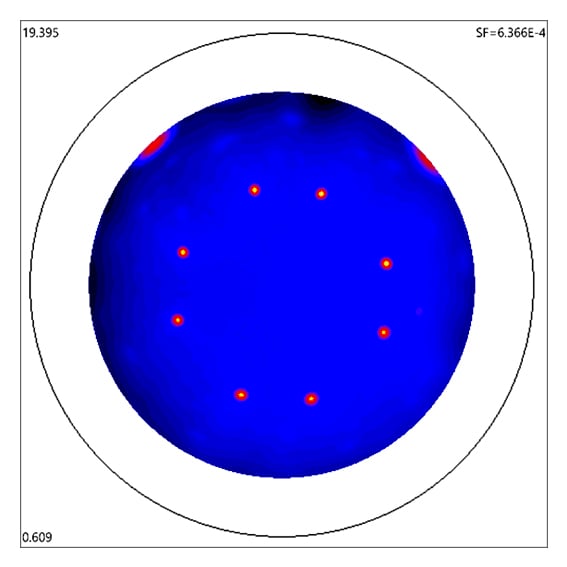

Texture Analysis

Identifies preferred crystal orientations that influence material behavior.

Why Use XRD?

The advantage of XRD analysis is its nondestructive nature, which also allows for the identification and quantification of phase differences within a material.

It is recommended that some input on sample chemistry be included for XRD analyses. Techniques like SEM/EDS, FTIR, WDXRF/EDXRF or XPS can help identify chemical information to aid XRD phase determination.

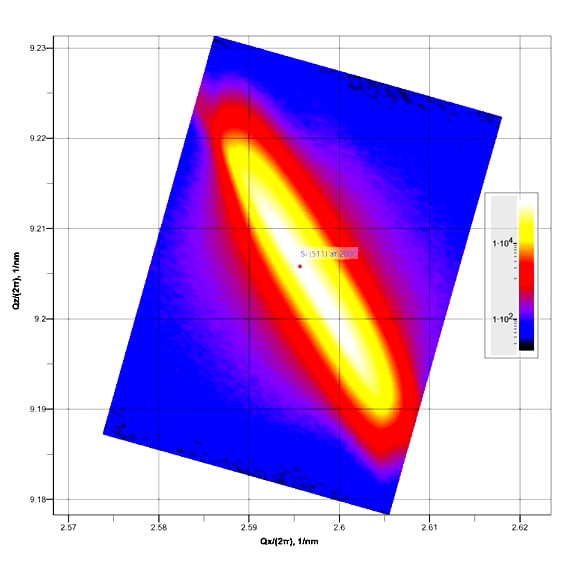

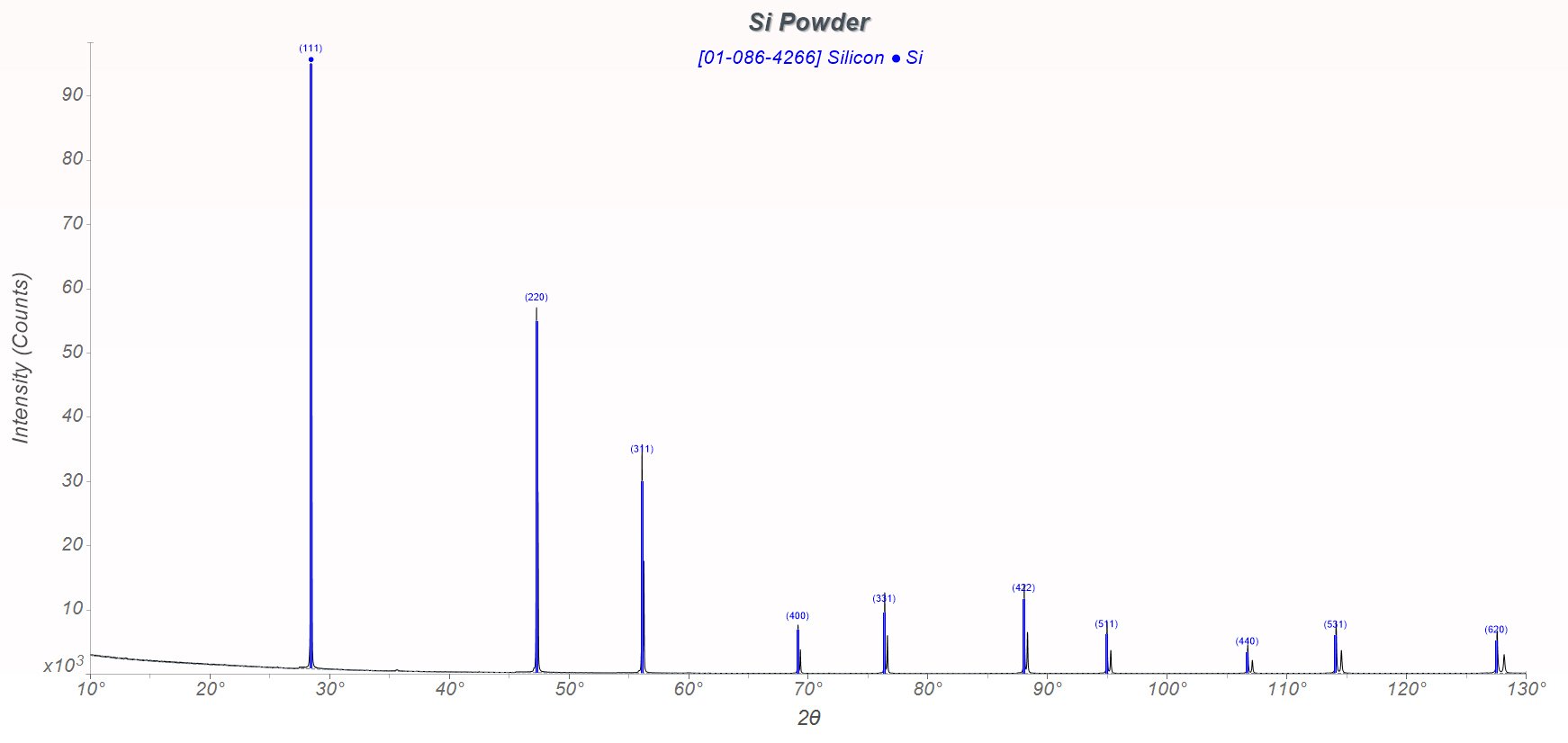

The picture above shows an out-of-plane Si powder XRD scan overlayed with a Si PDF card from the ICDD 2025 database.

Accurate Phase Identification

Pinpoint and quantify crystalline phases to confirm purity, detect impurities, and verify processing outcomes.

Detailed Structural Insights

Reveal lattice spacing, symmetry, and texture orientation, critical for optimizing material performance.

Stress and Size Evaluation

Measure residual strain and crystallite sizes, helping predict durability and functional reliability.

Working Principle

The basis of XRD comes from Bragg's law, which demonstrates that when X-rays encounter 3D arrangements of atoms in a crystal, most X-rays will interfere destructively, but at specific angles, they will interfere constructively. This constructive interference produces an XRD pattern that gives information on the crystalline lattice and helps identify a material's phase.

XRD is especially good at nondestructively identifying and quantifying differences in phases within a material, which it can do on bulk, thin-film materials, epitaxial films, and crystalline powders. XRD is often used to determine whether there are impurities or starting material within the final product and helps determine the weight percentages of each phase identified. It also assesses the percentage of crystallinity and crystallite size within a material.

Equipment Used for XRD:

Covalent has a 9kW rotating anode Rigaku SmartLab that allows for higher energy X-rays than other labs.

Rigaku SmartLab

- HyPix-3000 X-ray Detector.

- Rotating Anode X-ray Source.

- X-ray Source Tube Voltage: 20 to 40 kV.

- X-ray Source Tube Current: 10 to 20 mA.

- Triaxial Sample Stage.

- Biaxial Goniometer Head.

Key Differentiators

Strengths

- Covalent optimizes each XRD scan to the specific sample to allow for the best possible measurements.

- An invaluable tool for better understanding materials present within a sample.

- Non-destructive way of characterizing and quantifying the phases within a material.

- Can be used to learn about a material’s residual stress and even texture orientation.

Limitations

- XRD does not work with materials that are not flat or amorphous.

- A completely unknown sample can not be identified using XRD.

- Amorphous material tends to result in large halos at low angles in XRD patterns. Due to the width of the halos, XRD cannot identify what the material is, and the halos may even hide some crystalline peaks within them.

- Regular XRD scans can take around 20-30 minutes; however, more complex scans or samples with limited materials can lead to much longer scan times.

Unsure Whether XRD Is Right for You?

Learn how X-ray Diffraction can reveal crystal phases, structure, and strain—helping you make confident material decisions.

Sample Information

What we accept:

- For in-house XRD scans, samples must be solid and crystalline. External XRD sites can accommodate liquid samples for transmission XRD.

- For solid materials, 5mm minimum in length and width, 25mm typical, 150mm max.

- 0.5g powder minimum, 1-2g powder typical, no maximum amount of powder.

- 8-inch wafers are the maximum wafer size possible, but only for measuring the center of the wafer. Specific locations on an 8” wafer is not possible without breaking the wafer.

Use Cases

Semiconductor / Battery / Materials Industries

XRD is used for phase identification and quantification. There are some thin film materials which are sputtered and annealed that can be characterized by XRD for even film growth on the wafer from all parts of the sputter chamber and throughout each annealing step.

Pharmaceutical Industry

Relies on XRD analysis for phase identification and quantification.

Zeolite Material

XRD is used for phase identification and quantification of zeolite material to determine the purity of lab-grown material and whether any other compounds or starting material remained in the final process.

Graphitic Material

XRD is used for crystallite size analysis and for understanding Lc (graphite thickness, for c-axis (002) direction), La (graphite width in the layer sheet (100 and (110)) and degree of graphitization.

Complementary Techniques

Any technique with chemical or elemental analysis is a great complement to XRD. Though XRD is good for phase determination, it cannot determine a sample’s chemical makeup.

- X-ray reflectometry (XRR): A facet of XRD used for film thickness and density, and is related to spectral ellipsometry (SE) and transmission electron microscopy (TEM).

Transmission Electron Microscopy (TEM)

Images atomic structure, defects, interfaces with sub-nm resolution. Explore

Spectroscopic Ellipsometry (SE)

Measures thin-film thickness & optical properties. Explore

X-ray Reflectometry (XRR)

Optimized scans tailored to each sample for best measurements. Explore

Why Choose Covalent for Your XRD Needs?

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

What is X-ray Diffraction (XRD) used for?

XRD is used for understanding the phase, structure and texture of crystalline materials.

Is XRD a destructive technique?

XRD is a non-destructive technique.

What types of samples can be analyzed using XRD?

XRD can analyze crystalline powders, thin films, epitaxial films, and bulk solid materials.

Can XRD identify unknown materials?

XRD cannot identify unknown materials.

What information does an XRD scan provide?

XRD can provide phase confirmation, weight percentages of phases identified, percent crystallinity, residual stress, and even the texture of a sample.

What are the limitations of XRD?

XRD can only be run on crystalline and flat materials with known elemental composition.

What is the typical turnaround time for an XRD analysis at Covalent?

The typical turnaround time for an XRD analysis at Covalent is 5-7 days.

How accurate is XRD for quantitative analysis?

For complex phases (i.e., Zeolites with multiple interchangeable cations), the error can be between 5% and 10%. With simpler materials, the error will be less.