What Is Water Contact Angle Measurement?

Water contact angle measurement is a technique used to assess the wettability of a surface by water. This contact angle provides insights into the surface’s hydrophobicity or hydrophilicity, smaller angles indicate more wettable, hydrophilic surfaces, while larger angles suggest more water-repellent, hydrophobic surfaces.

High Accuracy

Measures contact angles from

5°-180° with ±1° precision for reliable wettability assessment.

Surface

Versatility

Can handle rough or irregular substrates, not just ideal smooth samples.

Quantitative

Insights

Provides both polar and dispersive surface energy components for complete surface characterization.

Why Use Water Contact Angle?

Water contact angles are commonly measured in materials science, coatings, and surface treatment analysis to characterize surface energy and cleanliness.

Wettability Assessment

Determines hydrophobicity or hydrophilicity critical for adhesion and coating performance.

Surface Cleanliness

Detects contamination or improper surface treatment before finishing operations like painting.

Process Control

Rapid, standardized measurements enable monitoring of surface treatment effectiveness and material consistency.

Covalent’s Capabilities Offer Water Contact

Angle for Quantitative Wettability

Assessment

Working Principle

Water contact angle measurements involve dispensing a droplet of water on a solid surface from a fine tipped needle or pipette and measuring the angle formed between the droplet’s edge and the surface. The measurement is performed by droplet shape analysis; a high-resolution camera is used to photograph a backlit droplet on a surface and automated image analysis software identifies the droplet edges and fits the contact angle with the substrate.

Equipment Used for Water Contact Angle:

Ossila Contact Angle goniometer

- Angle range: 5° to 180°.

- Maximum measurement speed: 33 ms (30 fps).

- Maximum camera resolution: 1920 × 1080.

- Typical droplet volume: Microliter scale.

Key Differentiators

The ability to accurately measure surface free energy and wettability on rough or irregular surfaces, not just smooth lab samples. Covalant’s advanced contact angle methods allow for reliable and quantitative analysis, even on challenging substrates; producing precise results for both polar and dispersive energy components where traditional methods often fail.

Strengths

- Rapid, inexpensive and sensitive assessment of surface chemistry and cleanliness.

Limitations

- Doesn’t provide insight into the nature of possible chemical contamination on surfaces, requires further spectroscopic testing to identify.

Unsure Whether Water Contact Angle Is Right for You?

Covalent has a range of complementary techniques to characterize surface chemistry and understand the measured contact angle and surface free energy.

Sample Information

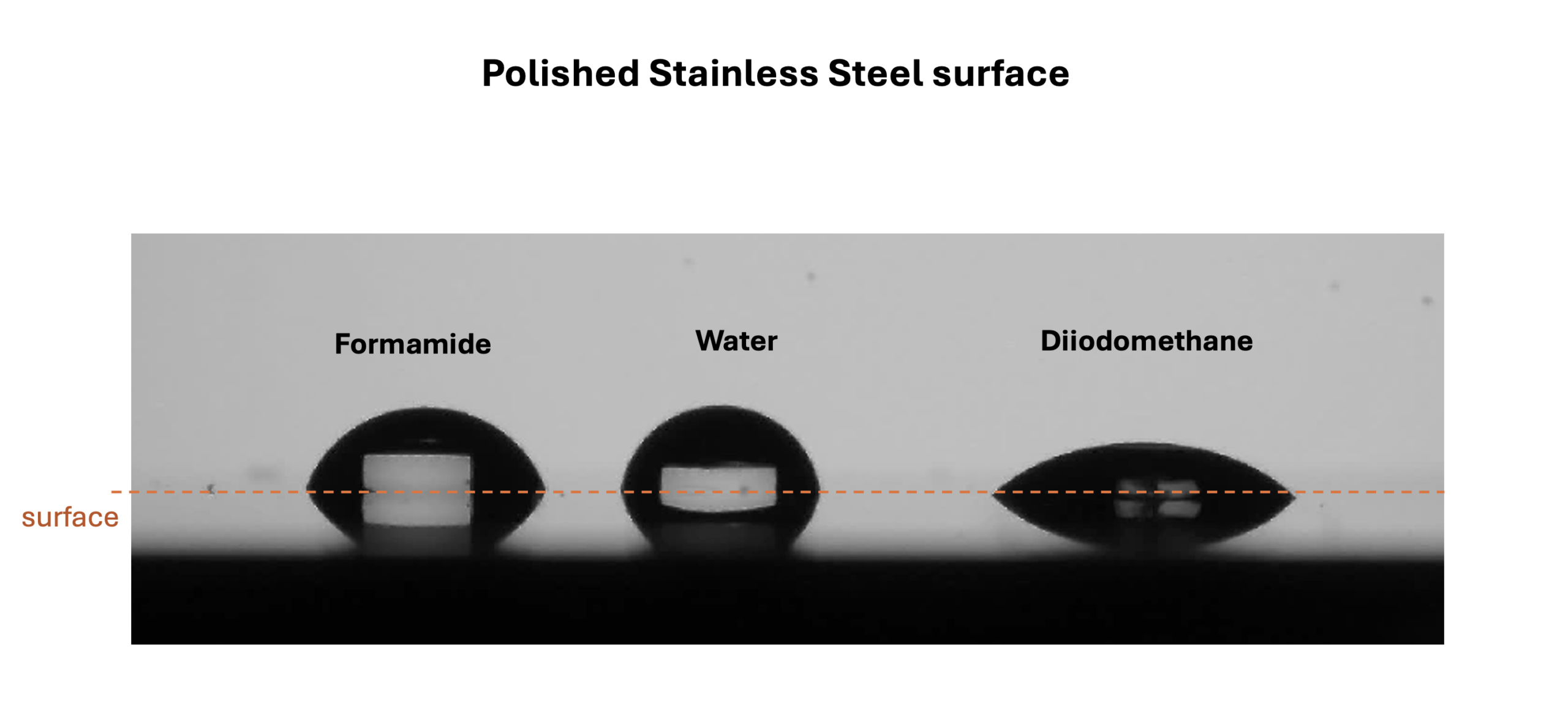

The contact angle images illustrate how surface chemistry controls wetting behavior through interactions with liquids of different polarity. On polished stainless steel, the nonpolar liquid diiodomethane spreads extensively, while polar liquids such as water and the highly polar formamide form more rounded droplets, indicating a surface dominated by dispersive interactions. In contrast, on the silicon wafer, formamide and water exhibit pronounced spreading due to strong polar and hydrogen-bonding interactions with the native oxide surface, whereas nonpolar diiodomethane wets less effectively. Together, these measurements clearly demonstrate how contact angle analysis differentiates polar and dispersive surface energy components, highlighting its value as a sensitive and non-destructive method for characterizing material surfaces.

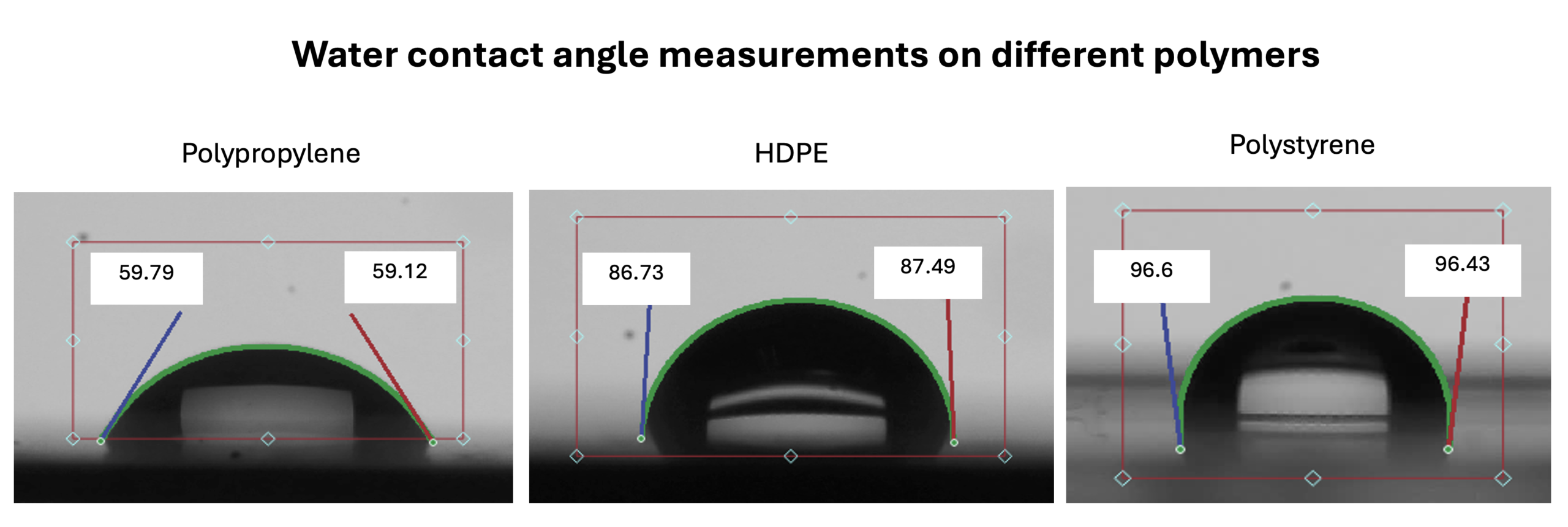

Water contact angle measurements on common polymers highlight both the sensitivity and diagnostic value of contact angle analysis. For polypropylene, the measured average contact angle (~59.5°) deviates strongly from literature values (~99°), immediately indicating significant surface contamination or chemical modification that would not be apparent from visual inspection alone. In contrast, HDPE shows a measured contact angle (~87°) close to reported values (~93°), with the small difference reflecting expected sensitivity to surface finishing and measurement conditions. Polystyrene exhibits excellent agreement between measured (~96.5°) and literature (~98°) contact angles, demonstrating reliable, well-defined surface behavior. Together, these results illustrate how contact angle measurements not only quantify surface wettability but also serve as a powerful tool for detecting contamination, assessing surface quality, and validating material processing in polymer and industrial applications.

What we accept:

- Solid surface capable of supporting a liquid droplet.

- Typical sample size is ~50x50mm but smaller or larger is possible.

Use Cases

Painting & Coatings

- Determine if surfaces are sufficiently clean before painting or other finishing operations so paints and coatings will adhere reliably.

- Measure wettability and surface energy to predict how well a coating will wet, spread, and adhere to a substrate.

Semiconductor Manufacturing

Determine cleanliness and wettability after cleaning or plasma treatments to ensure proper film adhesion.

Biomedical Devices

Evaluate surface wettability to influence protein adsorption, cell response, and fluid behavior.

Complementary Techniques

- FTIR, XPS and ToF-SIMS enable chemical and elemental analysis of surfaces to identify contamination or further understand wettability and the origin of surface energy differences due to contamination or process changes.

- Surface free energy measures the total surface free energy as well as the polar and dispersive components.

Fourier Transform Infrared Spectroscopy (FTIR)

Rapid, non-destructive molecular fingerprinting across materials. Explore

Surface Free Energy (SFE)

Quantitative insight into surface energy for adhesion and coatings. Explore

Time of Flight Secondary Ion Mass Spectroscopy (ToF-SIMS)

Ultra-sensitive surface analysis with chemical imaging & depth profiling. Explore

X-ray Photoelectron Spectroscopy (XPS)

Measures surface elemental composition and chemical states. Explore

Why Choose Covalent for Your Water Contact Angle Needs?

Covalant’s surface free energy measurement delivers rapid, standardized results that make it easy to monitor surface treatment effectiveness and material consistency, enabling tighter process control and fewer product failures.

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

Why is measuring water contact angle important?

Measuring water contact angle is important for understanding a material’s surface wettability, cleanliness, and surface energy. These factors directly affect adhesion, coating performance, and bonding behavior.

How is water contact angle measured?

Water contact angle is measured by placing a droplet of water on a surface and using optical imaging with automated image-analysis software to determine the angle formed between the droplet and the surface.

Does surface roughness or contamination affect water contact angle measurement?

Yes. Both surface roughness and contamination can significantly affect water contact angle measurements by altering surface wettability and introducing variability in the results.