What Is IPC Compliance Testing (IPC Compliance)?

IPC (formerly known as the Institute of Printed Circuits) is a global trade association dedicated to standardizing the manufacturing and assembly of electronic products. Since 1957, IPC has published hundreds of standards and is recognized as one of the most widely used authorities on electronics compliance standards. IPC standards provide Electronics Manufacturing Services (EMS), Original Equipment Manufacturers (OEMs), and third-party inspection labs with a framework for evaluating product quality. Certified technicians and engineers can consistently assess acceptability and identify defects during inspections by following these guidelines.

Global Manufacturing Standard

IPC defines the worldwide benchmark for electronic assembly quality and consistency.

Certified Inspection Expertise

Follows IPC-A-610 criteria to assess solder joints, component placement, and cleanliness across product classes.

Integrated Analysis Approach

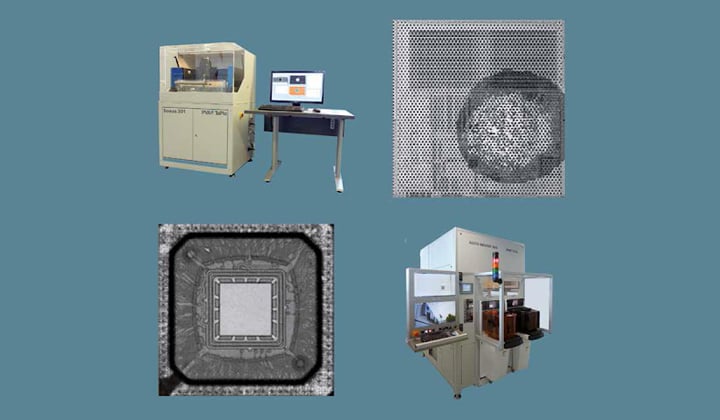

IPC inspections are complemented by advanced techniques like CT, IC, and SAM for comprehensive defect verification.

Why Use IPC Compliance?

Covalent recommends using IPC standards to ensure consistent quality and reliability in your electronic products. IPC standards provide clear, industry-accepted guidelines, and utilizing them can help manufacturers, engineers, and inspectors identify and address defects and issues efficiently. This ultimately reduces costly rework, improves overall customer satisfaction, and can enhance your credibility and competitiveness in the global electronics market.

Reliable and Consistent Quality

Ensures electronic assemblies meet defined acceptability and reliability requirements.

Reduced Rework and Failures

Early defect detection minimizes costly repairs, delays, and customer returns.

Enhanced Market Credibility

Demonstrates compliance with globally recognized standards, strengthening customer trust.

Working Principle

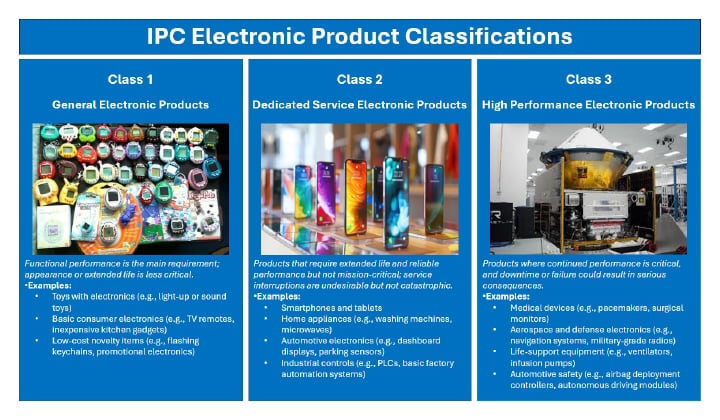

Covalent offers an IPC-A-610 inspection, which provides a standardized method for evaluating the visual and structural quality of electronic assemblies. The inspection uses detailed criteria and high-resolution imagery to assess solder joints, component placement, cleanliness, and mechanical integrity. This supports classification-based judgments across product classes 1 through 3, ensuring inspections align with the intended use of the product. The IPC standard not only enables inspectors to consistently identify acceptable conditions, process indicators, and true defects, but it also aligns with IPC training and certification programs. Ultimately, this enables subjectivity and ensures uniform application. The IPC-A-610 inspections also integrate well with related standards such as IPC-J-STD-001 and IPC-A-620 for comprehensive quality assurance.

Equipment Used for IPC Compliance:

VHX-6000 Digital Microscope

A digital microscope or other magnification system can be used to examine soldier joints, traces, and other fine details often under magnifications between 5x and 30x. Good lighting is critical to highlight surface imperfections or contamination.

- Dynamic Microscope Tilt Range: -60° to 90° from vertical.

- Magnification Range: 20x to 2000x.

- Maximum Field of View 15.24 mm (lateral) x 11.40 mm (vertical) at 20x magnification.

- Illumination Modes: customizable bright-field, dark-field, and mixed lighting.

- High-precision, automated, in-situ dimensional analysis.

Nordson Dage Quadra 7 X-ray

For hidden soldier joints, x-ray inspection systems are used. To protect sensitive components during inspection, it’s necessary to use ESD protection equipment like wrist straps and grounded workstations.

- 30–160 kV, 20 W.

- 100 nm feature recognition.

- 7 MP flat panel digital detector.

- 30 fps framerate.

- 0–70° oblique angle view.

- 20 × 17.5” inspection area.

- Geometric magnification up to 2.5k× & total magnification up to 68k×.

- High Dynamic Range (HDR) enhancement software.

- X-Plane CT scanning of BGA solder balls.

- Dosage control for X-ray sensitive samples.

Key Differentiators

Strengths

- Built on globally recognized standards for consistent evaluation of visual and structural quality.

- Helps ensure products meet quality requirements, reducing variability and subjectivity in assessments.

- Early defect detection improves product quality and minimizes costly rework or field failures.

- Covalent’s IPC certification programs ensure inspectors are properly trained for consistent standard interpretation.

- Using IPC standards builds trust with customers and OEMs, reinforcing manufacturer reputation.

Limitations

- Primarily focuses on visual and structural acceptability; does not assess functional or electrical performance without additional tests.

- Inspection can be time-consuming, especially for large or complex assemblies.

- Requires skilled inspectors to avoid misinterpretation.

- Maintaining certification involves ongoing investment and costs for businesses.

- Standards may not always reflect cutting-edge technology or unique product requirements, potentially requiring custom inspection criteria.

Unsure Whether IPC Compliance Testing Is Right for You?

Learn more about using IPC Compliance testing services today.

Sample Information

This image is a blue-themed infographic titled “IPC Electronic Product Classifications” and is divided into three vertical sections. Each section represents a different IPC-A-610 product.

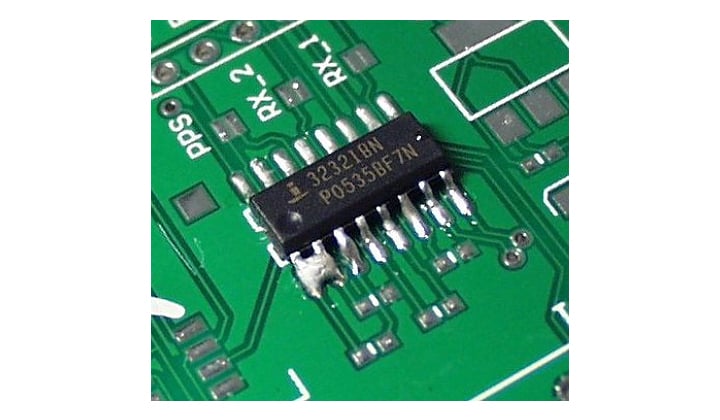

This image shows an IC component with excess solder, which has caused a “bridging” defect in the bottom left pins. This defect could cause concerns during an IPC-A-610 inspection, as it may lead to reliability or electrical issues like shorts or stress points.

What we accept:

To conduct an IPC acceptability inspection, inspectors typically need:

- Fully assembled or partially assembled printed circuit boards (PCBs).

- Wire harnesses, or enclosures, depending on which IPC standard is applied.

- Inspectors must be given engineering documentation that indicates the product’s classification—Class 1 (General), Class 2 (Dedicated Service), or Class 3 (High Performance)—as this determines the level of inspection detail and acceptable defect criteria.

Use Cases

Materials Science

- Automated Optical Inspection: Utilizes automated vision systems to identify defects and imperfections in materials.

- X-Ray Analysis: Examines internal structures of materials through

non-destructive testing.

Energy & Battery Research

- Battery Cell Assemblies: Ensures the quality and integrity of battery cells during manufacturing processes.

- Solder Joint Inspection: Evaluates solder joints within electronic battery components.

Semiconductor

- Printed Circuit Board (PCB) Testing: Validates the electrical connections and structural integrity of printed circuit boards.

- Conformal Coating Inspection: Checks the even coverage and thickness of protective coatings on PCBs.

Complementary Techniques

- Acoustic Microscopy (Scanning Acoustic Microscopy—SAM): Acoustic microscopy uses high-frequency sound waves to inspect for subsurface defects such as delamination, voids, and cracks in non-visible layers. This is valuable for inspecting underfill, die-attach, and encapsulated components. IPC-A-610 doesn’t address these internal issues, so SAM is a powerful nondestructive complement for critical assemblies or hidden features.

- Computed Tomography (CT Scanning): Provides a 3D, nondestructive view of an entire assembly. It allows inspectors to visualize internal features like solder voids, component misalignment, or internal short circuits without disassembling the board. Unlike IPC-A-610’s surface-level assessment, CT gives a comprehensive picture of building integrity and hidden defects—ideal for complex, densely packed assemblies.

- Cross-Section Analysis (Microsectioning): Cross-sectioning involves cutting and polishing samples to reveal internal structures, such as solder joint quality, plating thickness, and barrel fill-in through-hole components. This technique can uncover issues like cold solder joints, voids, or delamination that may not be visible in a standard IPC-A-610 inspection. It’s beneficial for validating process integrity during failure analysis or sample qualification.

- Ion Chromatography (IC): Ion Chromatography is used to detect ionic contamination—residues from flux, cleaning agents, or handling that could cause corrosion or electrical leakage. While IPC-A-610 might identify visual residues, IC quantifies contamination levels, especially in cases where the surface appears clean but fails long-term reliability. It’s crucial for verifying cleanliness in high-reliability products like Class 3 assemblies.

Scanning Acoustic Microscopy (SAM)

Locates internal flaws like cracks, voids, and delamination. Explore

Why Choose Covalent for Your IPC Compliance Needs?

At Covalent, our Failure Analysis team includes multiple certified engineers with extensive experience in electronics acceptability inspections, ensuring expert support for product qualification and failure investigations. Backed by a comprehensive suite of advanced analytical tools and a deep bench of technical specialists, Covalent is uniquely positioned to perform high-quality inspections and deliver thorough, data-driven follow-up analysis. This integrated approach helps clients quickly identify root causes, validate product reliability, and accelerate time to market. Contact us today to learn more about Covalent’s depth of capabilities in IPC compliance and how we can work together today.

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

How often should IPC compliance inspections be performed?

There is no requirement for the frequency of these inspections, but they are typically done at the end of each major step in production, such as IPC-6012 at PCB fabrication, IPC-A-610 at surface mount technology assembly, and IPC J-STD-001 at soldering processes (e.g. wave, manual).

Can IPC compliance testing be customized for unique or proprietary electronics?

Not in the sense of altering the scope of the standards themselves. IPC standards are specific to certain stages and technologies of manufacturing. Where proprietary or new technologies have no IPC standards, only those portions of the process that fall under IPC standards can be claimed as compliant.

What documentation or reports will I receive after an IPC inspection?

If there are defects, the report will cite the relevant IPC standard and the clause of the standard that will be applicable to the nonconformance indicating what is needed for correction.

Is IPC compliance required for all electronic assemblies?

No. Although IPC compliance is not required by law or regulation, the IPC standards are considered best practices for industry, and many companies use them worldwide to ensure consistency, reliability, and manufacturability of products.

How does IPC compliance testing help prevent product recalls or field failures?

IPC standards represent industry accepted criteria for materials, methods, workmanship and inspection, which help to reduce defect levels and variation, and help ensure sound manufacturing practices, reducing field failures and product recalls.