What Is Quality Control Testing?

Quality Control (QC) ensures that once materials and processes are perfected, they stay that way. It goes beyond testing raw materials to confirm that products continue to meet specifications, standards, and performance requirements as production scales, new suppliers come on board, or material batches vary over time. Effective QC keeps products performing consistently from early prototypes through full-scale production.

At Covalent, our quality control testing implements defined or modified test methodologies suitable for your application. We produce accurate and traceable data fast to help track your product consistency and performance over time.

Why Quality Control Testing Is Important

Quality Control Testing (QC Testing) is a critical safeguard before products are used by customers. We provide your technical teams with critical data and insights to ensure the materials and processes are within the acceptance criteria.

Strong QC programs help our customers:

- Detect deviations in material composition or formulation before they cause failures.

- Reduce downtime, scrap, or rework.

- Maintain consistency across batches & suppliers, or evaluate new suppliers.

- Demonstrate compliance with industry standards, especially if repeated or periodic verification is required.

- Support traceability and documentation for audits or other certifications.

When Do You Need Quality Control Testing?

A core part of Quality Control in product development is ensuring that what performs well in prototyping continues to perform the same way in production. As products move from lab to large-scale manufacturing, new variables and complexities are introduced — from additional suppliers and multiple material batches to shared equipment. Quality Control provides the framework and testing discipline needed to manage these variables, ensuring consistency, reliability, and compliance throughout the production process.

Quality Control is essential at every stage of production — from verifying raw materials to checking finished products before they reach customers. Ongoing testing helps ensure that materials, processes, and end products continue to meet defined performance and reliability standards over time.

At Covalent, clients often engage in ongoing quality control testing to support:

- Raw material verification: Confirming that incoming materials meet required specifications before production begins.

- In-process monitoring: Maintaining consistency and identifying drift during manufacturing.

- End product checks: Help verify that finished goods meet quality requirements.

These stages are especially critical when scaling from prototype to production volumes, managing multiple suppliers, implementing or renewing certifications, troubleshooting yield or performance issues, or adapting to process changes after equipment upgrades or material substitutions.

Common Types of Quality Control Testing

- Dimensional and Surface Inspection: Monitoring dimensions and surface conditions ensures that components and films meet critical specifications that affect fit, function, and reliability. Even small deviations in thickness, roughness, or geometry can lead to performance loss or assembly failure.

- Mechanical Property and Hardness Evaluation: Evaluation of mechanical properties, such as hardness, strength, and resistance to wear, becomes necessary for ascertaining a material’s resistance to operational stresses. This evaluation goes a long way in preventing failure, delamination, and deformation in a material used in stressful conditions.

- Chemical Composition Verification: Ensuring correct chemical makeup is essential because purity, stoichiometry, and contamination levels directly influence material performance. Deviations in composition can lead to poor durability, lower efficiency, or failure to meet regulatory or industry standards.

- Non-Destructive Structural Integrity Testing: Internal structure evaluation that does not cause harm to the component lets defects like cracks, voids, delaminations, and other hidden flaws be identified early. This functionality is key in maintaining product reliability, especially in cases where components are expensive and/or are classified as safety-related.

- Functional and Performance Testing: Evaluating how a part or material performs under intended conditions are used to confirm proper functionality in a given application. Such tests confirm characteristics such as electrical, optical, thermal, and adhesive properties.

- Environmental and Stability Testing: Assessing how materials change with temperature, humidity, or aging helps predict long-term reliability. Monitoring these factors identifies degradation pathways before they cause field failures.

Complimentary Solutions

- Material Verification: Ensures incoming or in-process materials match specified grades or standards, supporting QC compliance. It prevents defects and variability by catching incorrect or substituted materials early.

- Compositional Analysis: Provides precise elemental or chemical measurements to confirm materials fall within QC determinations. It identifies subtle deviations that may influence the product..

- Contamination Analysis: Detects unwanted particles, films, or residues that can cause failures or yield loss, making it a critical QC safeguard.

- Metallurgical Analysis: Evaluates microstructure and material properties to ensure they align with QC performance requirements. It helps detect processing issues such as improper heat treatment or grain structure abnormalities.

- Performance Optimization: Improves processes and operating conditions to reliably meet QC targets. By reducing variability and enhancing stability, it strengthens overall product quality and consistency.

Factors Influencing Quality Control Testing Frequency

If the solution requires recurring testing (e.g., for production consistency), key factors that dictate how often it should be done include:

- Production Volume and Batch Size.

- Criticality of the Component or Material.

- Tolerance Limits and Performance Specifications.

- Supplier Variability and Incoming Material Quality.

- Process Stability and Equipment Calibration.

- Customer or OEM-Specific QA Requirements.

- Regulatory or Industry Compliance Standards.

- Historical Defect Rates and Quality Trends.

- New Material Introduction or Process Changes.

- End-Use Application Risk Level.

In general, quality control programs designed by Covalent’s experts are formulated to provide insight and monitoring without being so onerous that they slow or impede the production process. These programs are designed to test at critical points of a process and prevent issues from progressing downstream. Our experts can consultatively help design a Quality Control program to fit your needs.

Industries That Benefit From Quality Control Testing

A variety of industries will benefit from quality control testing – nearly anything that requires consistency over time and at scale is a great fit for a well-designed QC Program. Some core applications include, but aren’t limited to:

Aerospace & Defense

Repeated tensile and fatigue testing to comply with MIL standard guidelines and requirements.

Medical Devices & Biotech

Monitoring to detect contamination or thickness variation via optical microscopy, XPS, or surface metrology techniques.

Energy & Batteries

TGA, DSC, and/or elemental analysis aimed at verifying separator, electrode, and electrolyte composition.

Food & Beverage Processing

Inspection for contamination, packaging seal integrity, and product consistency to meet safety and labeling standards.

Electronics & Semiconductors

Micro-defect detection, solder joint integrity, and process capability analysis (Cp, Cpk) for high-volume production.

Automotive & EV Assembly

End-of-line inspections, functional testing of components, and torque/cycle validation in high-throughput environments.

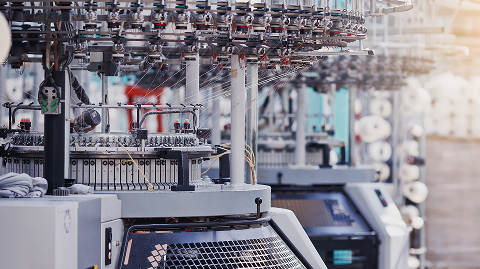

Textiles & Apparel

Fabric quality checks for color consistency, tensile strength, and stitching durability across production lots.

Plastic & Polymer Manufacturing

Dimensional checks, material hardness testing, and mold consistency audits.

Consumer Appliances

Functional, cosmetic, and environmental stress testing for assembled goods prior to distribution.

Why Choose Covalent for Quality Control Testing?

Covalent’s material science experts bring extensive experience in designing and delivering quality control services for diverse industries. We offer not just process monitoring and supervision, but also the resources to swiftly diagnose and address issues if unexpected results raise concerns.

Frequently Asked Questions

What information do customers need to provide for accurate QC testing?

Providing as many details as available will improve the QC testing protocol. Details like: composition, specification targets, tolerance ranges, and intended application helps ensure appropriate testing and accurate interpretation of results.

How much sample material is needed for QC testing?

The required amount depends on the type of test, but small samples are usually sufficient for most evaluations. Please contact our team for additional instructions.

How long does QC testing typically take?

Turnaround time varies by complexity, but many standard tests can be completed within 5 days.

How will the test results be delivered and interpreted?

Results are typically provided in a report that includes data, graphics, and clear explanations. Support is usually available to help interpret findings or discuss next steps.