What Is 4-Point Probe (4PP) Measurement?

The Four-Point Probe technique offers an accurate and reliable method for measuring electrical resistivity or sheet resistance. It eliminates the effects of contact and lead resistance.

Using 4 points (as opposed to 2 points) separates current and voltage paths, reducing measurement errors. It is non-destructive, quick, and easy to perform.

The method applies to a wide range of materials, from thin films to bulk materials and across a wide range of conductivity.

Multi‑Site Mapping

Rapidly maps sheet resistance uniformly across large areas.

Kelvin/4‑Wire Sensing

Separates current/voltage paths to remove contact resistance.

Broad Applicability

Works for thin films and bulk across wide conductivities.

Why Use 4PP Measurement?

- Non-destructive testing, high sensitivity, high accuracy, and fast.

- Powerful for surface and near-surface resistivity measurements.

- Perfect for semiconductor and thin film materials.

- Go-to analysis for both industries and R&D.

Analytical Depth

Measures sheet resistance or resistivity with high precision.

Material Compatibility

Works from thin films to bulk substrates.

Spatial Resolution

1.27 mm probe spacing enables localized Surface Measurements.

Working Principle

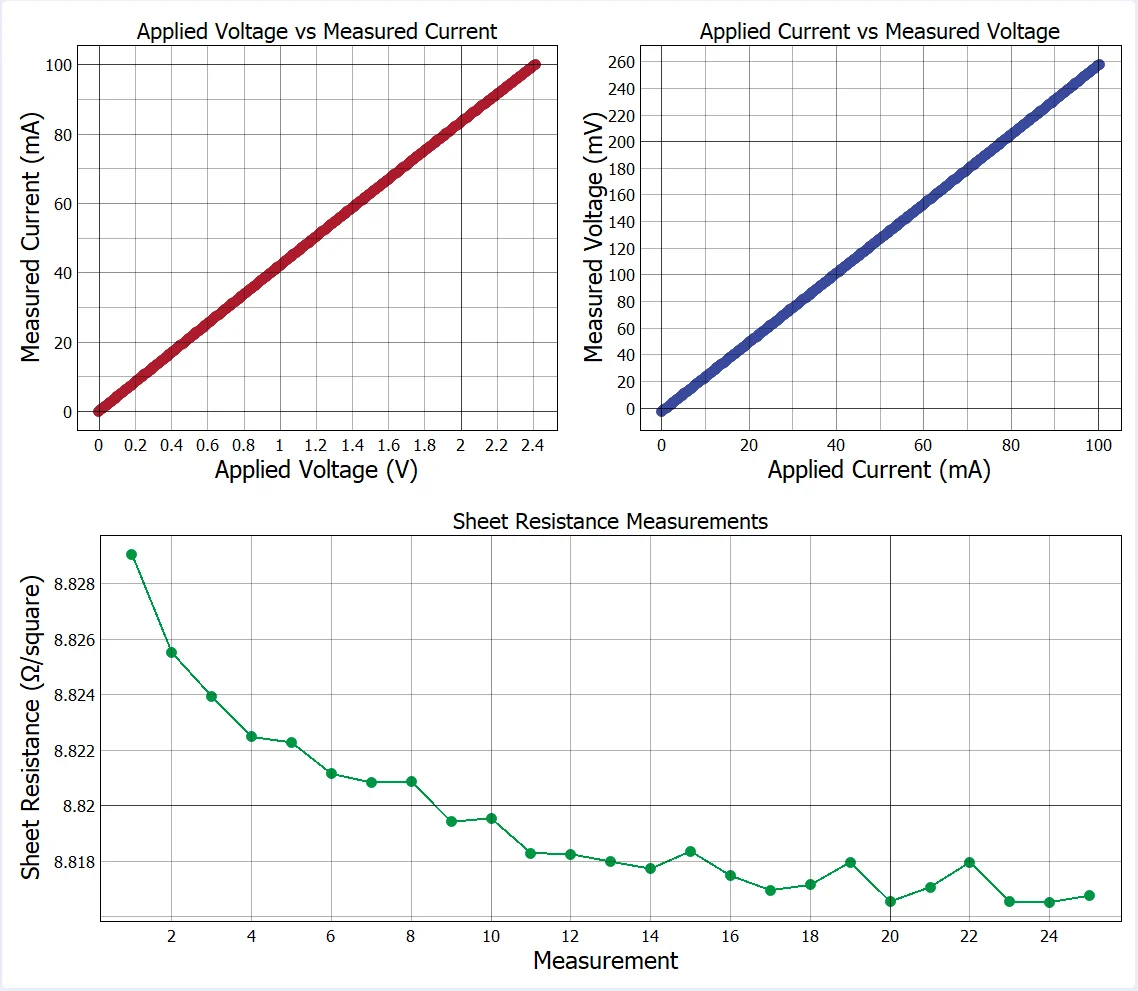

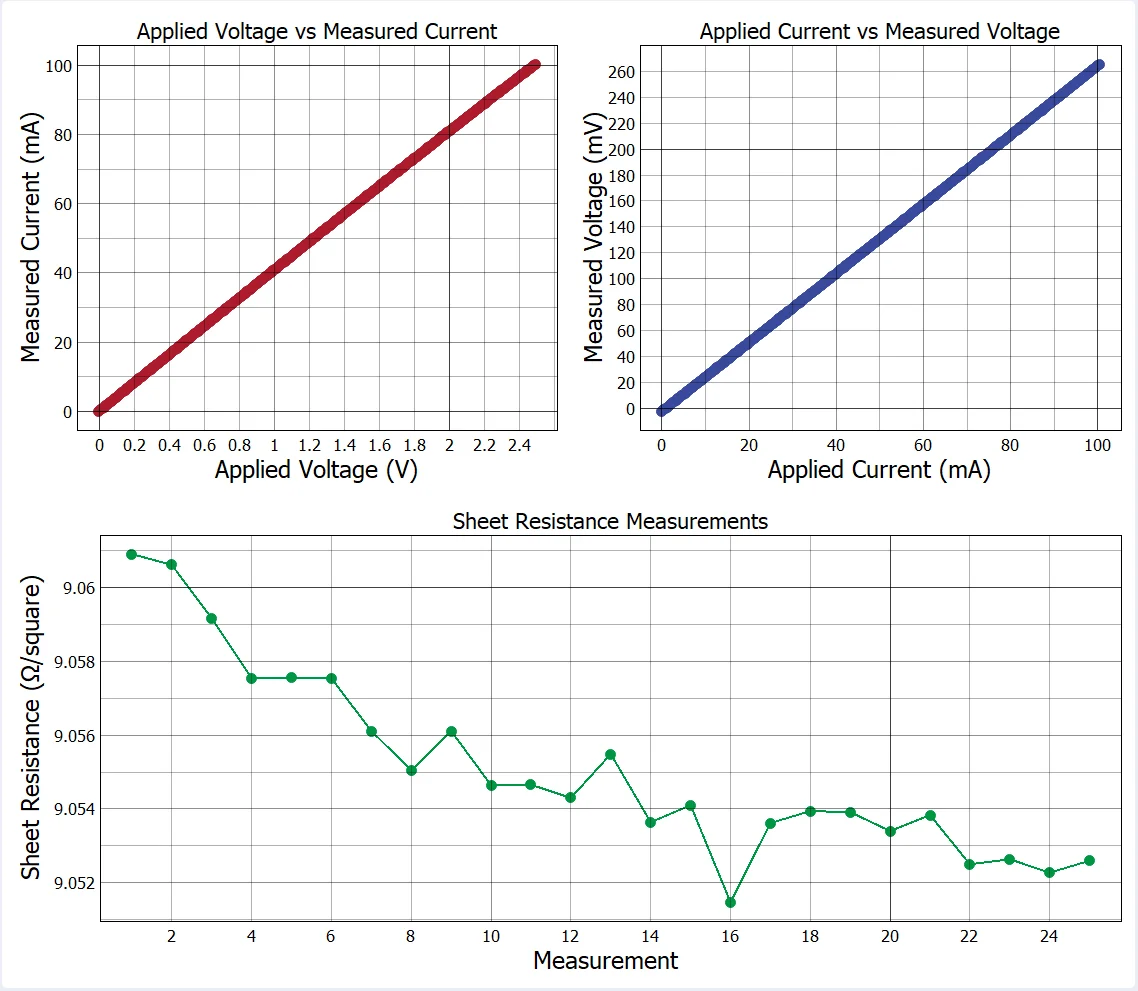

The 4PP technique uses a separate set of probes to flow current and measure voltage to eliminate the effect of contact resistance. Outer probes (1 and 4) pass a known current through the sample, and inner probes (2 and 3) measure the voltage drop.

Equipment Used for 4PP Measurement:

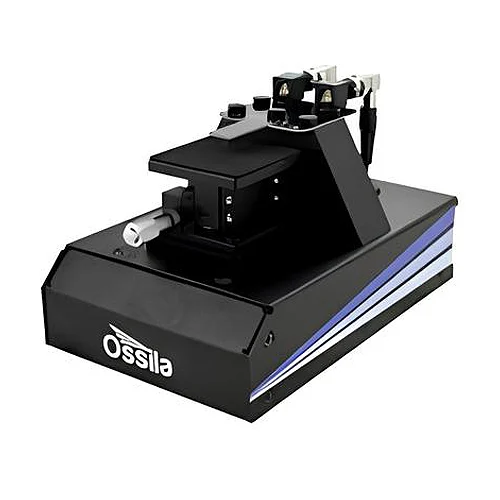

Ossila 4PP

- Probe spacing: 1.27 mm.

- Rectangular Sample Size Range:

- Long-edge Minimum: 5 mm.

- Short-edge Maximum: 60 mm.

- Circular Sample Size Range (Diameter): 5.0 – 76.2 mm.

- Maximum Sample Thickness: 10 mm.

- Acccuracy as low as ±1% for sheet resistance in 10 Ω – 10 kΩ range.

- High reproducibility, with deviation below 1% for most measurements.

Key Differentiators

The Four-Point Probe delivers precise, non‑destructive sheet resistance and resistivity data with rapid throughput. It supports diverse materials, from semiconductors and transparent conductors to metals and polymers, and scales from spot tests to mapped surveys.

Consider the following capabilities and constraints when selecting it for your workflow.

Strengths

- Non-destructive, powerful, fast, and accurate technique for surface resistivity measurements.

- Broad material compatibility with:

- Silicon and compound semiconductors.

- Transparent conductive oxides (e.g., ITO).

- Metal films and foils.

- Graphene and 2D materials.

- Conductive polymers.

Limitations

- Lack of depth resolution.

- Surface roughness, probe alignment, and contact stability can limit effective resolution, especially at small scales.

- No fragile, small, or highly curved samples.

- Minor surface damage risk.

Unsure Whether 4PP Is Right for You?

Talk to our experts for fast, accurate sheet‑resistance guidance today.

Use Cases

Semiconductor

A semiconductor R&D team needed a fast way to measure resistivity to understand the impact of various doping recipes for silicon wafers. Covalent used 4PP to measure the sheet resistance directly on the wafers and translate it to resistivity. Our clients were able to quickly iterate the diffusion conditions, saving the client weeks using 4PP.

Display Manufacturing & Consumer Electronics

A display manufacturer needed to confirm the homogeneity of ITO coatings across glass panels used in touchscreens. Our team mapped sheet resistance at various locations. Thanks to 4PP’s quick and non-destructive QC tool, manufacturing could move forward with confidence without the need for further lithography or contact pads.

Complementary Techniques

- Accurate thickness measurement is necessary for resistivity values. This can be obtained using a mechanical cross-section.

- Delayering techniques such as chemical or plasma etching might be necessary to test specific layers of a multilayer stack.

- Other techniques, such as scanning spreading resistance microscopy (SSRM) or conductive AFM, may be more suitable for very fine or nanoscale features.

Atomic Force Microscopy (AFM)

Maps nanoscale topography and material properties with a sharp probe. Explore

Mechanical Cross-Section Analysis (X-Section)

Uncovers microstructures and defects causing performance issues. Explore

Why Choose Covalent for Your 4PP Needs?

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

What is the accuracy of Four-Point Probe measurements?

The accuracy of Four-Point Probe measurements is <+/-4%. The accuracy of sheet resistance in the 10 Ω – 10 kΩ range is ±1%.

Can Four-Point Probe testing measure the resistivity of ITO and other transparent conductive films?

Yes, 4PP is ideal for measuring the resistivity (or sheet resistance) of ITO films. It is also ideal for measuring other transparent conductive films, such as AZO, FTO siler nanowires, etc.

What is the minimum sample size and thickness for Four-Point Probe measurements?

The sample should be a minimum of 5.0 mm wide and a maximum of 10mm thick for sheet resistance ranging from 3mOhm/ sq to 10Mohm /sq. Samples should be a minimum of 12mm wide (with no maximum thickness) for sheet resistance ranging from 0.5mOhm/sq to 10GOhm/sq.

What are common sources of error in Four-Point Probe measurements?

The most common sources of errors originate from the sample size and geometry, for example, non-uniform thickness or inaccurate thickness. Resistivity also depends on the environmental temperature, and local heating from the current can alter results.

How does probe spacing affect measurement accuracy in Four-Point Probe testing?

The resistivity calculation assumes equal and precise probe spacing. Covalent probes are regularly checked for any irregularities. Measurement standards are also used before each measurement to confirm the tool’s accuracy and the probe spacing.