What Is Gas Adsorption Porosimetry?

Porosimetry is a broad term for a set of analytical techniques and data processing methods that are used to characterize porous materials. Physical adsorption, or Physisorption, involves gas molecules weakly attaching or adsorbing to a surface through weak Van der Waal’s forces. The BET surface area analysis method is a specific data processing method for a subset of physisorption data. Chemical adsorption, or Chemisorption, involves gases forming stronger chemical bonds with the surface, while vaporsorption looks at how vapors are absorbed.

Gas adsorption porosimetry is primarily used to determine the specific surface area, pore size distribution, and pore volume of solid porous or, in some cases, relatively non-porous materials. If a reactive gas is used as in chemisorption, then additional parameters such as active metal surface area, metal dispersion, oxygen storage capacity, and average crystallite size can also be determined.

Other details:

- Detects pore sizes from 0.35 to 500 nm with high reproducibility.

- Ideal for catalysts, refractory materials, battery materials, and pharmaceuticals.

- Precise temperature and pressure control ensure reliable data.

- Supports N₂, Ar, Kr, CO₂, H₂, and other gases for tailored analysis.

Analytical Depth

Reveals insight not detectable by optical technique.

Molecular-Level Insight

Quantifies how gases interact with solid surfaces to define structure and reactivity.

High Sensitivity

Detects even ultra-low surface areas and pore volumes with precision.

Why Use Gas Adsorption Porosimetry?

- Gas adsorption porosimetry is the ideal technique for analyzing solid materials with pores in the nanoscale range, such as powders, granules, and flakes.

- Useful to obtain benchmark quality metrics under carefully controlled and reproducible conditions.

- One of the most sensitive techniques capable of measuring specific surface area and pore size distribution on a size and precision scale relevant to the material’s chemical interactions.

- Provides insights and useful metrics into catalyst activity, storage and transport properties, and gas adsorption capacity.

Surface and Pore Characterization

Measures BET surface area, pore size distribution, and pore volume of solid materials.

Active Sites and Reactivity Assessment

Evaluates active metal dispersion and surface area for accessibility and reactivity.

Functional Performance

Determines oxygen storage capacity, crystallize size, and related material properties.

Covalent’s Capabilities Offer Specific Surface Area Detection from 0.01 m2/g to 1000+ m2/g

Working Principle

Gas adsorption porosimetry works by first ‘cleaning’ the sample surface of any adsorbed moisture or gases through a process of heating under vacuum or inert gas flow. For analysis, samples are held at a specific temperature with cryogenic fluids, circulating coolers, or electric furnaces. Controlled doses of ultrapure gas are input into the sample cell, and the amount of adsorbed gas at increasing relative pressures is recorded. This data forms an isotherm, which is analyzed to determine relevant parameters using various physical and mathematical models.

Equipment Used for Gas Adsorption Porosimetry:

We use the Anton Paar Nova 800 for our high-throughput BET and general physisorption measurements, and the Quantachrome (now Anton Paar) Autosorb iQ series 7 for low surface area Kr physisorption and chemisorption or vaporsorption measurements. Certain custom experiments can be performed through dedicated and specialized equipment offered through our Connect partner network.

Anton Paar Nova 800

Specifications:

- Relative Pressure Range: 1E-7 to 0.999.

- Pressure Resolution: 1.2 x 1E-4 Torr.

- Pressure Accuracy: ±0.1% of full scale.

- Surface Area Range: 0.01 m²/g to no known upper limit.

- Pore Volume Limit (STP): 1.2 x 1E-8 cm3 .

- Detectable Pore Size Range: 0.35 nm to 500 nm.

- Reproducibility: <2%.

- Compatible Adsorbates: N₂, Ar, Kr, CO₂, H2, O2 and others.

Anton Paar Autosorb iQ 7

- Relative Pressure Range: 1E-8 to 0.999.

- Pressure Accuracy: < ± 0.15 % of reading.

- Surface Area Range: 0.01 m²/g to 1000+ m²/g.

- Detectable Pore Size Range: 0.35 nm to 500 nm.

- Ultimate Vacuum Pressure: 5 x 10-10 mbar.

- Compatible Adsorbates: N₂, Ar, CO₂, Kr, O₂, H₂, CH4, and more.

- Maximum Furnace Temperature: 1100 ℃.

Key Differentiators

At Covalent, we don’t just measure porosity – we help you understand it. Our Gas Adsorption Porosimetry services include full sample prep, testing, and analysis, supported by a range of complementary methods to reveal how structure, composition, and surface properties impact your material’s performance.

Strengths

- Efficient characterization of solid sample surface area, porosity, pore size distribution, active metal area, dispersion, and crystallite size.

- Accurate and reproducible surface areas down to 0.01 m²/g and pore sizes ranging from 0.35 to 500 nm.

- Automated in operando sample preparation.

Limitations

- Not optimized for large pore sizes (> 0.5 μm).

- Minimal insight into chemical composition, elemental distribution, or crystalline phases.

- Assumptions are made on pore structures to simplify the modeling algorithms.

Unsure Whether Gas Adsorption Porosimetry Is Right for You?

Learn how Gas Adsorption Porosimetry can give you precise insights into your material's surface area, pore structure, and active site behavior.

Sample Information

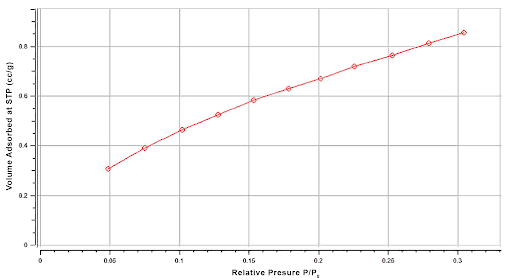

Example BET Surface Area plot measured with the Anton Paar Autosorb iQ sorption analyzer. This plot shows one of two powder samples analyzed with a mean surface area of 2.59 m2/g.

What we accept:

- A sample’s physical form must be solid.

- Samples with low volatility and vapor pressure are preferred to prevent interference with data collection and instrument performance.

- Our in-house instruments can measure pore sizes from 0.35 nm to 500 nm.

Use Cases

Battery Materials

Porosimetry testing is crucial in battery material characterization, including precursors and anode / cathode mixtures of LFP, NMC, graphite, carbon black, and other materials.

Catalysis & Energy

Evaluates catalysts and supports to maximize surface area, dispersion, and pore accessibility.

Air Purification & Carbon Capture

Measures adsorbents and MOFs to improve adsorption efficiency and capacity.

Pharmaceutical

Assesses drug delivery systems and excipients to optimize dissolution, stability, and bioavailability.

Complementary Techniques

- Capillary Flow Porometry (CFP): Determines through-pore size and connectivity by displacing a wetting liquid with gas, ideal for filters and membranes.

- Laser Diffraction: Measures particle size distribution to relate particle dimensions to surface area and porosity.

- Mercury Intrusion Porosimetry (MIP): Measures larger meso- and macropores by forcing non-wetting mercury into the structure under pressure, complementing gas adsorption’s focus on micro- and mesopores.

Capillary Flow Porometry (CFP)

Characterizes through-pores in wettable, permeable materials. Explore

Laser Diffraction Particle Size Analysis (LD-PSA)

Analyzes particle sizes by measuring light scattering. Explore

Why Choose Covalent for Your Porosimetry Testing Needs?

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

What is porosimetry, and why is it important?

Porosimetry is the term used for the general analysis of porous materials. It is important to characterize several metrics directly related to material performance in catalysts, battery materials, pharmaceuticals, and other materials, such as specific surface area, pore size, pore volume, metal dispersion, and active metal surface area.

What types of materials can be analyzed?

Generally, any solid material that is stable under analysis conditions can be analyzed, although there are limitations on the physical parameters that can be extracted. At Covalent, we analyze a wide range of materials, including battery electrodes, catalysts, refractory materials, metal-organic frameworks (MOFs), activated carbons, pharmaceutical excipients, and more.

What properties can porosimetry testing measure?

There are a wide variety of material properties that can be determined through porosimetry measurements, which depend on your material and the type(s) of porosimetry experiments conducted. These properties include, but are not limited to, specific surface area, pore size (distribution, mean, median, mode), pore volume, porosity %, active metal surface area, metal dispersion, average crystallite size, oxygen storage capacity, carbon dioxide uptake, water uptake, surface site density, bulk density, skeletal density, and oxygen vacancies, among others.

How does porosimetry differ from other analytical techniques?

Porosimetry differs from optical or electron microscopy techniques in its ability to measure nanometer-sized internal surface features in statistically relevant quantities. It is one of the most accurate techniques used to determine very fine-scale surface areas; however, it is not sensitive to internal porosity. Please inquire to find out which technique is best to solve the material challenge you are facing.

What industries benefit from porosimetry testing?

Since porosimetry isn’t limited to one type of material, it is applicable to various industries. Most relevant industries likely include energy storage and production, catalysis, carbon capture and storage, air purification, and pharmaceuticals.

How do I submit a sample for testing?

Contact our team to discuss your material and testing requirements. We’ll provide guidance on sample preparation, shipping, and turnaround times.

Can porosimetry testing help improve my material's performance?

Absolutely. Several of the parameters that can be determined through porosimetry measurements are directly related to material performance in crucial ways. By understanding or modifying factors such as surface area, pore structure, or metal dispersion, you can directly impact material efficiency, reactivity, adsorption, storage capacity, and drug delivery, among other types of improvements.