What Is Transmission Electron Microscopy (TEM)?

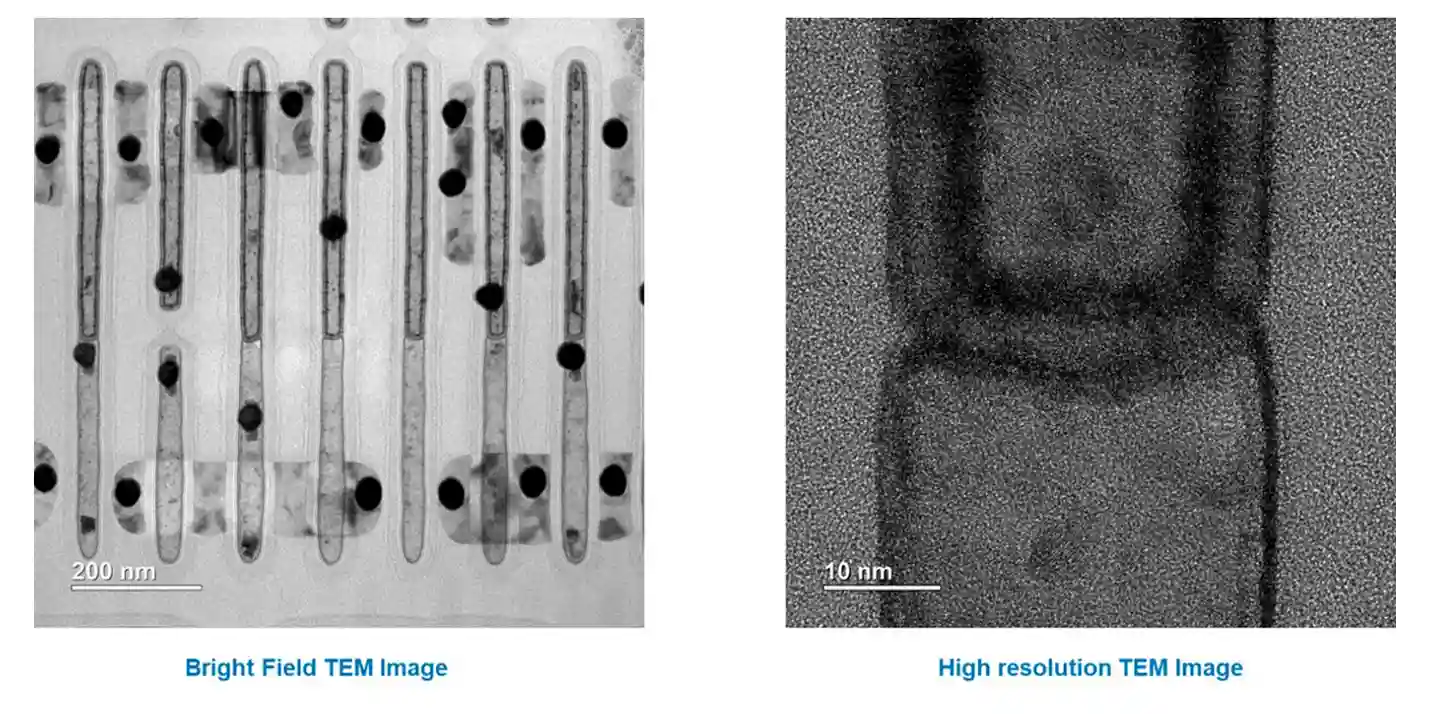

Transmission Electron Microscopy (TEM) is an imaging technique where a high-energy electron beam (typically ~200kV) is transmitted through a sample thinner than 100 nm. An image is formed by the interaction of electrons with the atoms in the sample.

Abbreviations:

- BFTEM: Bright-Field TEM.

- HRTEM: High-Resolution TEM.

- DF-TEM: Dark Field TEM.

- STEM: Scanning TEM.

- EDS: Energy Dispersive Spectroscopy.

- EELS: Electron Energy Loss Spectroscopy.

- SAD: Selected Area Diffraction.

- PED: Precision Electron diffraction.

Atomic-Scale Resolution

Achieves sub-nanometer imaging for precise structural analysis.

Multi-Mode Imaging

Supports TEM, STEM, HRTEM,

DF-TEM, and SAED for diverse applications.

Comprehensive Material Analysis

Measures layer thickness, defects, dislocations, and crystal orientation.

Why Use TEM?

TEM is the best technique to study crystal defects, grain boundary interactions, and dislocation analysis, as we can visualize the atomic arrangement directly.

TEM provides information at the atomic scale, providing very high accuracy of measurements. It is often used instead of SEM when a better resolution is needed, and instead of X-ray diffraction, when we want to study local structural information of the crystal/defects.

Unmatched Precision

Provides atomic-level insights beyond SEM and XRD capabilities.

Failure Analysis and QC

Identifies defects, contamination, and dislocation origins for reliable product development.

Cross-Industry Applications

Useful for semiconductors, batteries, aerospace, metallurgy, and nanomaterials research.

Working Principle

In a TEM, a high-energy electron beam is applied to a very thin sample (a lamella), which is prepared to be electron-transmissive i.e. typically 20 to 50 nm thick.

As the beam passes through the sample, scattering interactions occur between its electrons and the atoms present, which alter the intensity of the transmitted beam. These scattering events can produce several types of contrast in the final image, including: amplitude contrast (arising from atomic number and mass/thickness), phase contrast (from quantum phase shifting due to multiple scattered beams’ interference), diffraction contrast (from crystal structure and orientation), and more.

Different imaging modes on the TEM can target specific types of contrast over others, facilitating specialized analysis of relevant information.

From the images, we can obtain layer thickness measurements, morphology, shape, and size of the nanoparticles, as well as any inclusions (defects) or delamination of the layers.

Equipment Used for TEM:

Talos™ F200X G2 TEM

- Talos has the Super-X EDS system with 4 SDD detectors, helping with faster EDS data acquisition.

- TEM Line Resolution: ≤ 0.10 nm.

- STEM Resolution: ≤ 0.16 nm.

- Maximum Tilt Angle with Double Tilt Holder: ± 35° alpha tilt / ± 30° beta tilt.

- Maximum Diffraction Angle: 24°.

- Electron Source: High-Brightness Field Emission Gun.

- Gatan OneView CCD: 16MP 4K camera.

- Quad-EDS Detectors for enhanced sensitivity and detection limits.

JEOL JEM-F200 Multi-purpose Electron Microscope

- The JEOL JEM-F200 is equipped with two large-area SDD detectors that simultaneously provide high-sensitivity analysis, with efficient data collection.

- JEOL JEM-F200 with cold-FEG will have high energy resolution (<0.33 eV) with EELS.

- Cold-Field-Emission Gun (CFEG) Electron Source.

- Accelerating Voltage: 80 kV or 200 kV.

- High current and beam stability = ultra-high spatial resolution.

- TEM Point Resolution: 0.19 nm.

- STEM-HAADF Resolution: 0.14 nm.

- High-res Electron Energy Loss Spectroscopy (EELS).

- Fine Structure/Oxidation State Determination.

- Plasmon Resonance Analysis (CFEG supports zero-loss peak).

- Gatan GIF Continuum ER Image Filter for Energy Filtered TEM (EFTEM).

Key Differentiators

| Property | TEM |

|---|---|

| Common Applications | Layer thickness measurements, critical dimension (CD) and gate oxide analysis, interface quality assessment, dislocation density/type studies, crystal structure and orientation analysis, nanoparticle/nanowire/nanotube/quantum dot imaging, defect origin and location identification. |

| TEM vs STEM | TEM uses a nearly parallel electron beam for full-field imaging; ideal for crystal structure and diffraction analysis. STEM uses a focused convergent beam scanned point by point; better for localized EDS/EELS analysis. |

| Analytical Depth | Measures particle morphology (size, shape, distribution), grain and pore sizes, layer thickness at sub-nanometer resolution, defects (point defects, dislocations, stacking faults, interfaces, grain boundaries), lattice structure, crystal orientation, and 3-D tomography of particles or defects. |

| Material Compatibility | Metals, semiconductors, polymers, glass, and other materials that withstand high-energy electron beams. |

| Spatial Resolution | Sub-nanometer resolution. |

Strengths

- TEM is a very high-resolution technique, which has 10-20 times better resolution than SEM. TEM is for atomic scale imaging, SEM is for nano-scale imaging.

- TEM can measure layer stacking with much more precision than SEM.

- Interface quality of the layers can be imaged at atomic level which is not possible by SEM.

- TEM is good for studying dislocations, grain boundaries, crystallographic information which is not possible by regular SEM imaging.

- TEM is used for its better resolution capabilities and reliability in measurements.

Limitations

- Destructive technique.

- Elaborate sample preparation.

- Beam sensitive materials, biological samples not suited.

- Expensive tools.

- Information comes from a small portion of the sample. Need to do multiple samples for statistical analysis.

Unsure Whether TEM Is Right for You?

Learn more about using Transmission Electron Microscopy services today.

Sample Information

What we accept:

- Physical form: Thin transparent lamella with a thickness of less than about 100 nm.

- Necessary properties: Electron Transparency.

- Minimum sample size: 2 mm sample size, even small can be handled if needed.

- Samples should be conductive for lamella preparation, or else samples is coated with metal coating to help with conduction.

Use Cases

Semiconductor Equipment

TEM enables critical dimension measurements and gate oxide analysis for next-generation fabrication tools. Advanced imaging reveals equipment-induced defects and contamination sources at atomic resolution, ensuring manufacturing precision and yield optimization.

Semiconductor Manufacturing

Layer thickness validation and epitaxial interface quality assessment drive process control in semiconductor manufacturing. TEM identifies dislocation origins, stacking faults, and dopant distribution patterns critical for device performance and reliability.

Consumer Electronics

Miniaturization demands in consumer electronics require precise analysis of interconnects, solder joints, and component interfaces. TEM characterizes failure mechanisms in flexible displays, memory devices, and power management circuits.

Battery & Energy Storage

Electrode material degradation, solid electrolyte interfaces, and lithium dendrite formation analysis optimize battery performance. TEM reveals structural changes during cycling, enabling development of safer, longer-lasting energy storage systems.

Aerospace & Defense

Critical component reliability in extreme environments requires atomic-scale defect analysis. TEM characterizes superalloy microstructures, coating adhesion, and fatigue crack initiation in turbine blades and structural components.

Metallurgy

Grain boundary engineering and precipitation hardening mechanisms benefit from TEM’s crystallographic analysis capabilities. Phase transformation studies and corrosion interface examination guide alloy development for industrial applications.

Complementary Techniques

- SEM or cross-section SEM provides larger field of view to locate the features of interest for TEM analysis.

- STEM integrated with TEM can be used for Z-contrast imaging and EDS and EELS are typically collected in STEM mode.

- XRD provides bulk crystallographic information (phase, lattice parameters), while TEM gives local crystal data.

Scanning Electron Microscopy (SEM)

Images surface topography and composition with electrons. Explore

Scanning Transmission Electron Microscopy (STEM)

Provides atomic-scale imaging and spectroscopic mapping. Explore

X-ray Diffraction (XRD)

Non-destructive analysis of crystal phases, lattice, and strain. Explore

Why Choose Covalent for Your TEM Needs?

Covalent's experienced cross-industry team provides exceptional data quality within 24-48 hours, accelerating your research timelines.

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

What is the maximum sample thickness for reliable TEM analysis?

Ideally, the sample thickness for TEM analysis is less than 100 nm.

How do you prevent beaming damage in sensitive polymer materials?

A low-dose imaging technique or Cryo-TEM will be applied to minimize the electron beam damage when analyzing sensitive polymer materials.

What measurement error should I expect for nanoscale dimensional analysis?

The TEM were calibrated to within 1% error.

Can you determine specific dislocation types from high-resolution TEM images?

Yes, dislocation types can be determined from two-beam diffraction conditions and high-resolution TEM images.

What minimum feature size can your TEM equipment reliably resolve?

Our TEM can resolve sub-nanometer size features.

How accurately can layer thickness be measured in multilayer structures?

The TEM were calibrated to within 1% error.

Do you offer cryo-TEM services for temperature-sensitive biological samples?

Yes, we offer Cryo-TEM services for temperature-sensitive biological samples.