What Is Thermomechanical Analysis (TMA)?

Thermomechanical Analysis (TMA), also referred to as thermal expansion analysis or dimensional stability testing, is a technique that measures the dimensional change of a material in relation to temperature, time, and force.

In a TMA measurement, a small probe is placed in contact with the sample. As the temperature is ramped up or held constant, the instrument records the displacement of the probe caused by the sample’s dimensional changes. Depending on the mode, this can include expansion, compression, penetration, or flexural response under load.

Complete Thermal Insight

Reveals expansion, shrinkage, and softening for real-world performance understanding.

Failure Risk Reduction

Detects CTE mismatches and instability early to prevent material failures.

Deeper Material Profiling

Pairs with DSC or DMA for fuller thermal-mechanical characterization.

Why Use TMA?

Thermomechanical Analysis helps understand how materials expand, contract, or deform under changing temperatures or applied forces. This information is critical for evaluating dimensional stability, thermal expansion coefficients (CTE), softening points, and glass transition temperatures (Tg).

TMA ensures that materials maintain structural integrity in real-world conditions, especially when exposed to thermal stress. With sub-micron displacement precision and multi-mode testing options, it provides a complete picture of mechanical and thermal behavior. These insights guide material design, prevent thermal failures, and improve product reliability across applications.

Multi-Mode Testing

Performs expansion, penetration, tension, and compression for varied material analysis.

High Precision

Measures sub-micron displacement and applies controlled force for accurate results.

Wide Test Range

Operates from −70 °C to 600 °C under air or inert gas for diverse material types.

Working Principle

In TMA testing, the sample sits on a stage with a light load applied by a probe to track dimensional change as temperature changes. The instrument follows a programmed heating or cooling profile while recording the probe’s displacement. A purge gas, such as nitrogen, is typically used alongside.

Thermomechanical analysis can be performed in the following modes:

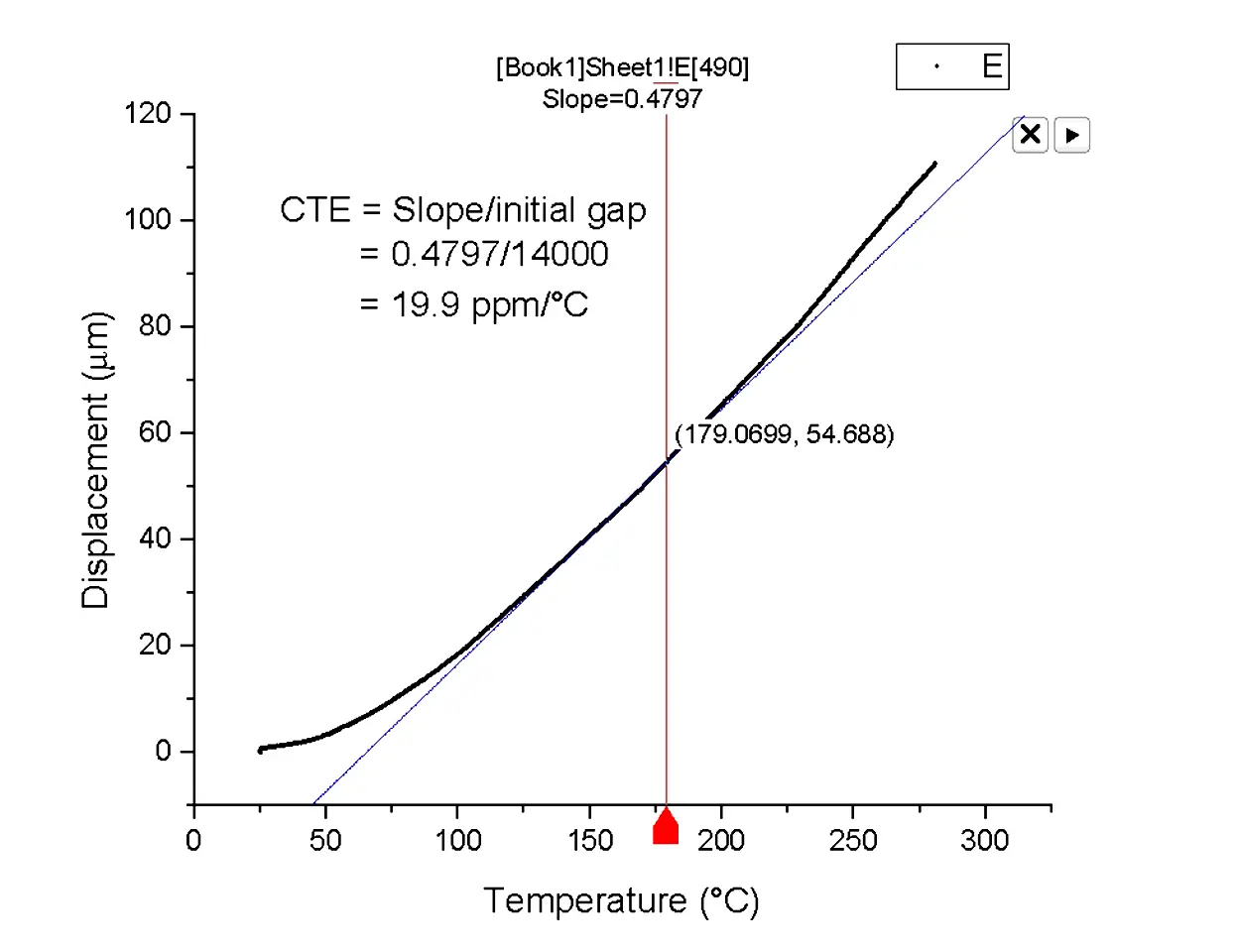

- Expansion mode: measures the coefficient of thermal expansion (CTE) and dimensional change.

- Penetration mode: Identifies softening point or glass transition temperatures (Tg).

- Tension/compression mode: Measures mechanical response under axial load.

Plotting displacement against temperature will reveal when the material transitions or changes mechanically.

Equipment Used for TMA:

Anton Paar MCR 702

The MCR 702 MultiDrive is a combination DMA / Rheometer with the flexibility and precision to facilitate a huge array of test mode options.

- Maximum Torque: 230 mNm.

- Normal Force Range: 0.005 N to 50 N.

- Temperature range:

- Tensile: -150 C – 350 C.

- 3 pt bend: -150 C – 350 C.

- Compression: – 100 C – 280 C.

Key Differentiators

Thermomechanical Analysis (TMA) measures how materials expand, shrink, or deform with temperature and force, revealing key properties like CTE, Tg, and softening points. With sub-micron displacement precision, multiple test modes (expansion, penetration, compression, tension), and a wide −70 °C to 600 °C range, Covalent’s TMA delivers high-accuracy insights into dimensional stability and thermal performance. Ideal for thin films, laminates, polymers, and composites, it helps detect early failure risks and ensure long-term reliability.

Strengths

- Provides a variety of modes and probes.

- Able to test various samples and form factors.

Limitations

- 600°C limit.

- Not suitable for high-force compression, tensile testing, refractory ceramics, or high-temperature metals.

- Requires small samples; macroscale specimens need sectioning.

- Humidity control is not available.

Sample Information

What we accept:

- Physical Form: Thin films, foams, coatings, laminates, small polymer or composite samples.

- Geometry: Ideally flat, uniform surfaces; size ≤10 mm × 10 mm × 5 mm.

- Special Requirements: Soft or adhesive materials may require substrate mounting.

Use Cases

Electronics & Semiconductor

TMA helps assess CTE mismatch between polymers and metals in multilayer film stacks, preventing delamination, warping, and reliability issues in packaging and device assembly.

Polymers & Plastics

Used to determine glass transition temperature (Tg), softening point, and dimensional stability in polymers like PET and engineering thermoplastics, ensuring consistent performance under heat.

Composites & Laminates

Evaluates expansion and shrinkage behavior to maintain structural integrity during thermal cycling or curing, crucial for aerospace, automotive, and industrial composites.

Medical Devices

Supports material selection and validation by comparing softening, deformation, and recovery in medical-grade polymers exposed to sterilization or operating temperatures.

Advanced Materials & Coatings

Measures expansion and contraction in low-k dielectric films, foams, and specialty coatings, helping predict material behavior during processing or in end-use environments.

Complementary Techniques

- DSC (Differential Scanning Calorimetry) is used for precise glass transition temperature (Tg) and melting point determination.

- DMA (Dynamic Mechanical Analysis) is suggested for viscoelastic behavior and storage or loss modulus determination.

- FTIR (Fourier Transform Infrared Spectroscopy) is great for identifying chemical degradation during thermal cycling.

Differential Scanning Calorimetry (DSC)

Quantifies heat flow for material optimization. Explore

Dynamic Mechanical Analysis (DMA)

Characterizes thermal and mechanical properties of soft materials. Explore

Fourier Transform Infrared Spectroscopy (FTIR)

Rapid, non-destructive molecular fingerprinting across materials. Explore

Why Choose Covalent for Your TMA Needs?

Covalent has a depth of knowledge and expertise with TMA analysis services, applications and is highly capable of pairing TMA with other complementary techniques, which provides for insights into the desired material.

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

What kinds of samples can be tested with TMA analysis services?

TMA analysis services can test a variety of materials, including thin films, laminates, adhesives, polymers, and composites.

Do the samples need to conform to a specific geometry?

Yes, small flat samples (≤10 mm) are ideal. Covalent offers help with sample sectioning or mounting if needed.

Can I run tests in an inert atmosphere?

Yes, a nitrogen purge is standard.

How long does the TMA testing service take?

The turnaround is typically around two weeks after the sample is received. We offer expedited options.