What Is Performance Optimization?

Material testing isn’t always about determining whether a specific function can be performed or a parameter can be met. More often, it’s about turning insights into action and understanding what’s happening within a material today to drive better performance tomorrow. By examining how materials behave under real or simulated conditions, Covalent’s Performance Optimization services help enhance the reliability, efficiency, and longevity of materials across a wide range of applications.

Why Performance Optimization Is Important

Improving material performance can reduce manufacturing costs, enhance safety and reliability when components are part of critical assemblies, and extend the usable life of products and materials. Our customers also leverage our Performance Optimization services for competitive product analysis, ensuring their end products meet or exceed industry benchmarks. A Covalent-guided performance optimization service can help you:

- Ensure that materials perform predictably in the environments they’ll see during real-world usage and conditions.

- Improve performance under mechanical, chemical or thermal stress, either to achieve or exceed regulatory, competitive or operational benchmarks.

- Tune processes for consistency and reliability of output.

- Prevent field failures and costly recalls.

When Do You Need Performance Optimization?

Our customers engage Covalent’s Performance Optimization services at a variety of points in the product development lifecycle:

- During research and development, to improve prototyped designs or adjust prototypes for scalability to production volumes.

- During production and manufacturing, to correct drift from established standards, improve the energy efficiency or yield of a process, or when incorporating materials from new suppliers or modified equipment into an existing process.

- After a product has been produced, to evaluate field failures, improve durability and performance under unexpected or changing conditions, or when regulatory or other critical requirements change.

Performance Optimization may include chemical, thermal, optical, or structural analysis, depending on the outcomes we’re attempting to achieve and the specific performance metrics we’re optimizing for.

Common Types of Performance Optimization

The number of optimizations is as large as number of processes. Our material characterization services can help you with:

- Process Stability and Control Optimization: Helps manufacturers reduce variability by identifying critical material properties and establishing data-driven process control limits.

- Root-Cause and Failure Analysis: Diagnoses production defects and failures using advanced imaging and chemical analysis to restore yield.

- Material Specification Optimization: Defines and refines material specifications that ensure consistent performance and reduce supplier-related production issues.

- Process Parameter Optimization: Testings are used to determine optimal process conditions and improve production efficiency.

- Contamination Identification and Mitigation: Identifies contamination sources and recommends targeted cleaning or surface-treatment solutions.

Best Practices for Effective Performance Optimization

Performance Optimization programs at Covalent work best when we have clear targets and objectives. Usually this means:

- Known current state variables (we can help assess where a material or component is at if this isn’t known).

- Understood success criteria: What standards are we trying to meet? Are they fixed regulatory requirements, or performance-based standards where the outcome is operational in nature and there may be multiple paths to success?

- Defined parameters: Performance improvements only matter if they make sense in the real world. The best solutions are practical, scalable, and cost-effective. By defining what success looks like from the start—within the context of your manufacturing process, pricing strategy, and service capabilities—we help ensure every optimization delivers real business value.

Complementary Solutions

Performance Optimization vs. Consultancy:

Performance Optimization seeks to improve a particular outcome in a material, a process, a product, etc. by finding areas of inefficiency and then applying targeted enhancements. Consultancy, on the other hand, provides general knowledge, guidance, and interpretation of expertise to help a client make informed decisions about issues. Although Performance Optimization provides actual performance improvement, Consultancy supplies the bigger picture and enabling structure necessary for long-term success.

Industries That Benefit From Performance Optimization

Industries that often leverage our performance optimization services are varied, but tend to focus on applications where materials are difficult to access once manufactured, where material performance affects safety, or where performance gradients are a significant competitive differentiator. Examples include:

Energy & Batteries

Optimize electrode resistance, thermal management, and degradation resistance to improve battery life, prolong lifespan (increase the total charging cycles possible before a battery must be replaced), or reduce the cost of manufacturing.

Medical Devices & Biotech

Improve the lifespan or performance of surfaces, particularly surgical implements or implantable devices, to improve efficacy and lifespan.

Automotive & Aerospace

Reduce weight, improve fatigue resistance under thermal and mechanical stress, or address impact and vibration-related performance of materials.

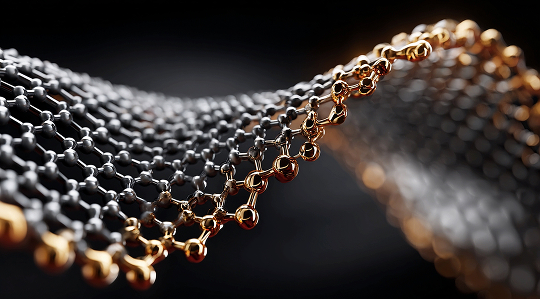

Polymers & Composites

Improve strength to weight ratios, improve reliability of manufacturing processes, or refine composites to improve operational performance or reduce material & manufacturing costs.

Why Choose Covalent for Performance Optimization?

Covalent’s domestic facility in Sunnyvale, California, isn’t just a collection of equipment that can perform comprehensive analysis and testing of your material. It’s a gathering place for top experts & scientists who combine theoretical and practical backgrounds with a passion for helping our customers find material solutions. We’ve armed our experts with top-of-the-line equipment, market-leading data analysis tools to analyze & interpret the results we produce, and white-glove solutions that we develop in concert with our customers to design programs that fit your Performance Optimization goals.