What Is Metal Testing?

Metals Testing is a comprehensive process that examines and measures the various properties of a metal to understand its structure, composition, and how it will behave under different conditions. It involves exploring microscopic features, such as grain size, crystal structure, alloying elements or inclusions, and macroscopic properties like hardness, tensile strength, toughness, and corrosion resistance. The goal is to establish the relationship between the characteristics and to predict how the metal will perform in its intended application or under specific environmental stresses.

Detailed analysis is crucial across many industries, including aerospace, automotive, construction, and electronics. It helps engineers and scientists choose suitable materials to optimize manufacturing, ensure safety and reliability, troubleshoot failures, and develop new metal alloys with improved properties. Techniques used for metals testing are varied and include optical and electron microscopy, different spectroscopy methods (such as X-ray fluorescence and optical emission spectroscopy), and a broad range of mechanical tests, including tensile, hardness, and impact testing.

Why Invest in Metal Testing?

- It validates the mechanical and chemical performance of metals, ensuring they behave as expected under real-world conditions, matching design and application needs.

- Reduces the risk of component failure in high-stress environments, helping identify weaknesses or inconsistencies that could compromise safety and function.

- Guides selection and process optimization, enabling informed decisions on material composition and processing methods for improved performance and cost efficiency.

- Ensures regulatory and specification compliance by confirming that materials meet industry standards and customer requirements, preventing legal and contractual issues.

- Drives innovation in material development, enabling engineers to experiment with and refine new alloys or treatments with a deep understanding of material behavior.

- Improves lifecycle assessment and sustainability, enabling more accurate predictions of material durability and recyclability, supporting sustainable design decisions.

When Should Metal Testing Be Performed?

Metal testing ensures component integrity, reliability, and performance at all manufacturing stages.

- During R&D for new alloy formulations.

- When selecting alloys for the process or its optimization.

- For incoming material inspection and supplier validation.

- After thermal or mechanical processing (e.g., welding, forging).

- Before certification or customer delivery.

- Post-failure to determine the root cause.

Consistent testing throughout the production cycle minimizes risk, enhances quality control, and improves overall manufacturing efficiency.

Industries That Use Metal Testing

Every industry that uses metals relies on metal testing to ensure performance, safety, and compliance in critical applications. Here are the dominant ones:

Aerospace & Defense

Confirming alloy integrity and fatigue resistance.

Automotive

Ensuring strength and corrosion resistance in structural parts.

Medical devices

Validating implantable alloy biocompatibility.

Energy

Characterizing materials exposed to high temperature and stress.

Electronics

Assessing the purity and microstructure of conductive elements.

Key Differentiators

Advantages

Appropriate metals testing and characterization will allow you to:

- Create a more successful product thanks to a better understanding of how mechanical and environmental stress perform.

- Save money by helping prevent failures, rework, and warranty claims through early detection of metal-related issues.

- Pass the regulator check by verifying that metal components meet industry-specific standards and certifications.

- Optimize your design by selecting the right metal alloy and heat treatments based on performance requirements.

- Reduce production delays by identifying inconsistencies or defects in metal stock before it enters the manufacturing process.

- Extend product lifespan by ensuring the resistance of metals to fatigue, wear, and corrosion.

- Enhance customer satisfaction with reliable, high-performance metal components.

- Streamline R&D by accelerating the development of metal parts through accurate performance data.

- Minimize liability risks by documenting thorough metal testing and quality assurance practices.

- Enhance sustainability by choosing recyclable metal alloys and increasing durability to reduce waste.

Limitations

Metals testing may not allow you to:

- Accurate predictions of real-world performance as lab conditions cannot always replicate complex service environments.

- Avoiding all failures, such as unexpected loading conditions, human error, or undetected defects, can still cause issues.

- Characterize every aspect of a metal without using multiple complementary methods, which can be time-consuming and resource-intensive.

- Capture long-term degradation fully, as some effects, such as corrosion fatigue or creep, can take months or years to replicate in the lab.

How Does Metal Testing Work?

Metal testing begins with the statement of the purpose of the testing, like analysis of alloy composition, confirmation of functionality, or investigation of failure causes. The specimen undergoes preparation in terms of cleaning, sectioning, or polishing in order to obtain representative data through accurate measurements. To obtain information regarding composition, structure, properties, and other data about a sample, highly specialized equipment is used by applying force, waves, or beams. Spectroscopy analysis, microscopic analysis, mechanical testing analysis, and X-ray analysis are performed independently yet complementarily to gain different information. The data obtained from this process are interpreted by skilled professionals and compared with specifications or requirements from the customer in terms of suitability and use. Finally, a detailed report highlights the conclusion and recommendations based on the analysis.

Types of Metals Testing and Measured Properties

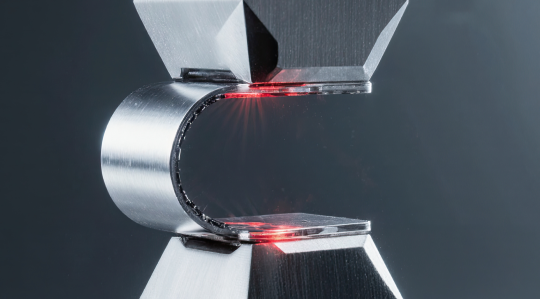

- Mechanical Properties are measured to evaluate how metals respond to forces and deformation through testing properties like hardness, elastic modulus, or residual stress.

- Structural Properties like phase, micro-defects, and grain size are assessed to understand internal features that influence performance.

- Composition and Chemical homogeneity are evaluated to confirm alloy composition and detect contaminants.

- Surface and Interface Properties are critical for wear, corrosion, or bonding performance. These include surface roughness, coating adhesion and uniformity, and oxide layer composition.

- Physical and Functional Properties, like electrical and thermal conductivity, and magnetic properties, are measured to evaluate performance.

How Are Results Tracked and Reported?

Data alone does not solve engineering problems. Interpretation does. At Covalent, we combine raw measurements with expert interpretations, spanning spectra, morphology, and root-cause insights. Our clients receive method details, annotated data, precise conclusions, and access to raw files, along with on-demand one-on-one sessions with our experts.

Our reports include:

- High-resolution spectra, maps, and profile outputs.

- Layer-specific analysis of composition, thickness, or topography.

- Quantified measurements with precision calibration.

- Interpretation aligns with the process stages of failure modes.

- Structured outputs, suitable for QA, regulatory, and development workflows.

Typical Applications

- Corrosion tests will help determine the correct alloy for specific conditions and prevent costly structural failures.

- Hardness testing ensures that components can withstand wear and mechanical stress during operation.

- Tensile testing identifies the load-bearing capacity of a material, helping prevent structural failure.

- Chemical composition analysis confirms material grade.

- Fatigue testing predicts how a material will perform under repeated loading.

- Weld analysis verifies joint quality and consistency, reducing the risk of cracks or separation under stress.

- Surface roughness measurement supports coating adhesion and friction control in precision applications.

Why Choose Covalent for Metal Testing Services?

Covalent’s surface and interface testing lab has a comprehensive suite of tools built to analyze metals with precision and speed.

Our scientists bring expertise in surface characterization, interface mechanics, and thin film analysis to every project.

Each test is custom-designed to match the material, objective, and scale of analysis. From method development to data interpretation, we focus on delivering high-resolution results that are fast, clear, and engineered for action.

Ready to get started? Request a quote or talk to our team.

Frequently Asked Questions

Can I send multiple alloys in a single batch?

Yes, however, please label and document each sample.

Do you offer consulting to interpret complex failures?

Yes, our experts provide in-depth analysis and expert insight.

What is the turnaround time?

The standard turnaround time is 5-7 business days; however, expedited services are available.

What is the difference between EDS and XRF for elemental analysis of metals?

EDS (Energy-Dispersive Spectroscopy) is typically attached to an SEM and provides localized, surface-level elemental data, which is helpful for microstructure mapping.

XRF (X-ray Fluorescence) is better suited for determining bulk or average composition and is a non-destructive technique. EDS offers higher spatial resolution, while XRF delivers faster results for overall composition.

Can I test coated or surface-treated metals without damaging the coating?

Yes, non-destructive techniques like XPS, SEM (in low-vacuum mode), or profilometry help examine coatings without causing damage. However, detailed analysis of internal interfaces or coating adhesion might require cross-sectioning or destructive methods such as nanoindentation tests.

Commonly Used Techniques for Metals Testing

- Mechanical Testing (Hardness, Fatigue, Nanoindentation): Quantifies strength, durability, and local mechanical properties. Validates designs, compares materials, tunes processes, and predicts service life.

- Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy (SEM-EDS): High-resolution imaging with elemental mapping to identify composition, contaminants, and failure sites. Accelerates material identification, process control, and root-cause analysis.

- Transmission Electron Microscopy with beam etching (TEM, FIB-TEM): Site-specific cross-sections and thinning enable atomic-scale imaging and chemistry. Pinpoints nanoscale defects, interfaces, and device failures with nanometer precision.

- X-ray Diffraction: Determines crystalline phases, lattice parameters, texture, and residual stress. Verifies specifications, purity, and processing outcomes for powders, bulk, and thin films.

- X-ray Photoelectron Spectroscopy (XPS): Measures surface elemental composition and chemical states. Verifies cleanliness, bonding, oxidation, and thin-film stoichiometry to optimize adhesion, corrosion resistance, and device performance.

Scanning Electron Microscopy (SEM)

Images surface topography and composition with electrons. Explore

Transmission Electron Microscopy (TEM)

Images atomic structure, defects, interfaces with sub-nm resolution. Explore

X-ray Diffraction (XRD)

Non-destructive analysis of crystal phases, lattice, and strain. Explore

X-ray Photoelectron Spectroscopy (XPS)

Measures surface elemental composition and chemical states. Explore