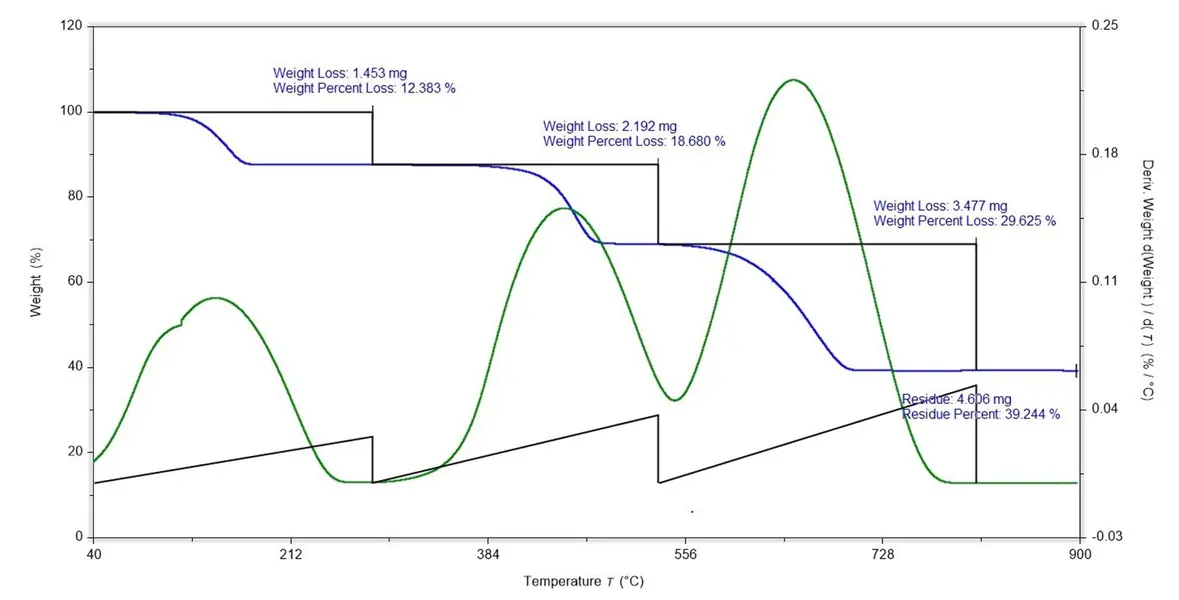

What Is Thermogravimetric Analysis (TGA)?

TGA provides critical insight into a material’s thermal behavior and composition in a single test. It allows for identification of moisture content, volatiles, organic vs. inorganic content, and thermal degradation points. This technique delivers high-resolution, quantitative data ideal for material screening, formulation studies, quality control, and material analysis.

High Sensitivity

TA Instruments TGA 5500 provides 0.1 µg balance resolution for precise material changes.

Atmosphere Control

Supports dual gas switching, inert/reactive gases, and extended isothermal analysis.

Why Use TGA?

TGA offers high sensitivity to mass changes and typically requires small sample quantity (10-50 mg). It is especially useful when assessing thermal stability, degradation kinetics, or identifying material constituents by decomposition behavior. Use TGA instead of differential scanning calorimetry (DSC) when you need quantitative mass-loss data rather than just heat flow data.

Assess Thermal Stability and Degradation

Tracks mass changes to evaluate material decomposition, moisture, volatiles, or ash content.

Quantitative Composition Analysis

Determines filler/resin content, residual solvents, or polymer lifetime through decomposition kinetics.

Small Sample and High-Resolution Data

Requires only 10–50 mg of sample, ideal for formulation studies, quality control, and research applications.

Working Principle

A sample is placed on a high-precision mass balance inside a temperature-controlled furnace. As the temperature increases (or is held constant), the system records any change in the sample's mass. The analysis is performed under inert or reactive gases (e.g., nitrogen or air) to understand thermal events such as evaporation, decomposition, or oxidation.

Equipment Used for TGA:

Covalent has a TA Instruments TGA 5500, the most advanced TGA, offering 0.1 µg balance resolution. This allows us to detect even the smallest material changes with exceptional accuracy.

TA Instruments TGA 5500

- Mass Sensitivity: 0.1 µg.

- Temperature Range: Ambient to 1200 °C.

- Controlled Heating Rate (up to 1000 °C): 0.1 to 500 °C / min.

- Nitrogen and Air Atmosphere.

Key Differentiators

- Features ultra-sensitive balance and programmable dual gas switching.

- Capable of high throughput runs with autosampler.

Differentiates Covalent from competitors through advanced gas switching, controlled environments, and integration with FTIR, GC-MS for evolved gas analysis (on request).

Strengths

- TGA provides a direct, quantitative measure of material composition, making it ideal for formulation verification, contamination analysis, and thermal degradation studies.

Limitations

- A minimum sample mass of 10 mg is required to obtain reliable and high-quality data.

- Complementary techniques like FTIR, MS (Mass Spectrometry), or GC-MS are often needed to chemically identify evolved gases.

- It is less effective for low-mass or low-volatility samples.

- Not ideal for highly reactive or unstable samples unless special precautions are taken.

Unsure Whether TGA Is Right for You?

Whether you’re looking for fast troubleshooting or ongoing support, Covalent’s TGA services are scalable solutions to meet your needs.

Sample Information

What we accept:

- Physical Form: Solids or semi-solids; powders, films, pellets, pastes.

- Volatility/Thermal Stability: Should be stable enough to handle programmed heating.

- Sample Size: Typically, 10–50 mg.

- Special Requirements: Must be dry or pre-conditioned unless moisture is being analyzed. Inert atmosphere recommended for sensitive organics.

Use Cases

Semiconductor

Residue analysis and contamination studies on semiconductor materials and components.

Biomedical

Polymer degradation profiling and stability assessment of drug carrier systems.

Aerospace & Automotive

Characterization of composites and adhesives used in structural and bonding applications.

Pharmaceuticals

Quantification of moisture content and residual solvents in pharmaceutical formulations.

Food & Beverage

Thermal stability evaluation and shelf life estimation for food and beverage products.

Energy & Battery Research

Characterization of separator and electrolyte behavior in energy storage systems.

Complementary Techniques

- DSC: For thermal transition analysis (e.g., Tg, melting point).

- EDX: For residue composition analysis post-TGA.

- FTIR and GCMS: To identify gases evolved during decomposition.

- TMA/DMA: For mechanical property changes with temperature.

TGA complements these techniques by providing accurate mass-loss profiles. For example, unlike DSC which tracks heat flow, TGA quantifies actual material decomposition or loss, offering compositional insight.

Differential Scanning Calorimetry (DSC)

Quantifies heat flow for material optimization. Explore

Dynamic Mechanical Analysis (DMA)

Characterizes thermal and mechanical properties of soft materials. Explore

Fourier Transform Infrared Spectroscopy (FTIR)

Rapid, non-destructive molecular fingerprinting across materials. Explore

Gas Chromatography-Mass Spectrometry (GC-MS)

Identifies and quantifies small organic molecules in mixtures. Explore

Thermomechanical Analysis (TMA)

Measures material dimension changes with temp, time, or force. Explore

Why Choose Covalent for Your TGA Needs?

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

What types of samples can Covalent test with TGA?

We analyze a wide range of materials — including polymers, composites, coatings, pharmaceuticals, electronics, and metals.

How sensitive is your TGA analysis?

Our TA Instruments TGA 5500 system offers 0.1 µg balance resolution and superior thermal stability, allowing detection of extremely small mass losses and fine thermal events that other systems might miss.

Can you identify what gases or decomposition products are being released?

Yes! We can couple TGA with FTIR or GC-MS to characterize evolved gases during decomposition, giving you chemical identification alongside the weight loss data.

How fast can I get results?

Standard turnaround is typically 5–7 business days, with expedited options available depending on sample complexity and volume.

What gas atmosphere can Covalent use?

Currently, we have nitrogen and air.