What Is Fourier Transform Infrared Spectroscopy (FTIR)?

Every material tells a story, and in materials science, and Fourier Transform Infrared Spectroscopy (FTIR) is how we read it. FTIR spectroscopy is a precise, non-destructive technique that analyzes how a material interacts with infrared (IR) light to reveal its molecular structure.

All materials are composed of chemical bonds, each with unique vibrational characteristics. When exposed to IR radiation, these bonds absorb specific wavelengths that correspond to their vibrational frequencies. These interactions result in unique FTIR spectra: graphs that act like a fingerprint of the sample, mapping chemical composition, structures, and bonds in detail.

At Covalent, we use advanced Fourier Transform Infrared Spectrometers to identify contaminants, validate polymer formulations, and investigate material failures with speed and clarity.

Non‑Destructive

Analysis

Preserves sample integrity while providing clear chemical fingerprints for structure identification.

Rapid Insights

Delivers fast, accurate results with minimal sample preparation, accelerating material analysis workflows.

Broad Material

Coverage

Effective across polymers, coatings, films, residues, and organic compounds, adaptable to a wide range of applications.

Why Use FTIR?

Covalent’s FTIR analysis delivers accurate results for real‑world applications. Our FTIR analysis supports micro‑level detection and advanced chemical investigations across complex materials. We excel at:

- Bulk chemical identification.

- Failure analysis in polymers and coatings.

- Surface contamination analysis.

- Oxidation, cross-linking, or degradation studies.

- Incoming material inspection.

Analytical Depth

Sensitive detection of surface contamination, oxidation, degradation, and failure at the micro‑level.

Material Compatibility

Works with solids, liquids, films, coatings, and polymers using transmission, reflection, or ATR modes.

Integration Power

Pairs seamlessly with Raman, SEM‑EDS, XPS, or GC‑MS, delivering comprehensive material characterization.

Working Principle

A typical FTIR analysis begins by directing IR light onto the sample through a device called an interferometer. This device is the core of a Fourier Transform Infrared Spectrometer (also known as a Fourier Transform IR Spectrometer or FTIR Spectrometer), which splits and modulates the light to produce an interferogram.

This signal captures how the sample responds to a broad range of infrared wavelengths and is then mathematically processed (the Fourier Transform) into an FTIR spectrum, more precisely, a set of FTIR spectra that depict absorbance or transmittance at different wavenumbers.

The resulting peaks (typically ranging from 4000 to 400 cm⁻¹) signify the sample’s chemical bonds and molecular structure.

Depending on the sample, different sampling modes are selected:

- Transmission Mode: IR light passes through the sample to the detector.

- Reflectance Mode: Light bounces off a reflective surface and back to the detector.

- ATR FTIR Spectroscopy: Measures shallow penetration depths into the sample using diamond or germanium ATR crystals.

Equipment Used for FTIR:

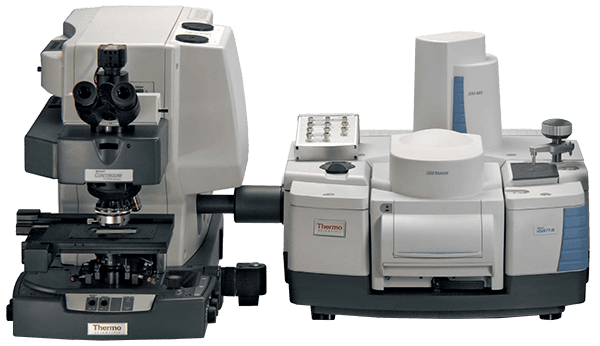

The Fourier Transform Infrared Spectroscopy lab at Covalent is equipped with industry-grade systems, carefully deployed to deliver high-resolution insights across a dynamic spectral range, at both macro and micro scales.

ThermoFisher Scientific Nicolet iS50 FT-IR Spectrometer

- Spectral range: 7800 to 350 cm⁻¹.

- Resolution: < 0.09 cm⁻¹.

- Wavenumber accuracy: < 0.005 cm⁻¹.

- Multi-detector configuration to support advanced analytical modes.

Integrated Accessories:

- Diamond ATR (standard and high-pressure) for durable or hard samples.

- Ge ATR for carbon-filled or opaque materials.

- Variable angle ATR for precision thin film analysis.

- Transmission mode for thin films and KBr pelletized samples.

- Reflectance mode for metallic surface coatings and contaminants on reflective surfaces.

ThermoFisher Scientific Nicolet Continuum IR Microscope

- 15x and 32x objectives.

- Detector options: Narrow-band MCT-A High performance (4000 to 750 cm⁻¹) and Narrow-band MCT-A (50um element, 4000 to 700 cm⁻¹).

- Sampling modes: Transmission, reflection, Ge ATR, and diamond cell transmission.

- ATR objectives: Dedicated with interchangeable Diamond, Ge, ZnSe, and Si crystals; integrated pressure sensor for robust sampling.

- Grazing angle objective: NA 0.99 for sensitive thin-film and surface analysis.

- Detector configuration: Dual detector bay supporting MCT-A, MCT-B, and InGaAs detectors for broad spectral coverage.

Key Differentiators

Our advanced FTIR systems combine analytical depth, broad material compatibility, and versatile sampling modes. Whether analyzing polymers, coatings, or trace contaminants, these capabilities ensure rapid, high-resolution insights tailored to solve real-world materials challenges with confidence.

- Analytical Depth: Transmission and reflection depth of analysis is the total thickness. Diamond ATR is ~2 µm depth, and Germanium ATR is ~0.66 µm to nm level depths, ideal for FTIR ATR spectroscopy.

- Material Compatibility: Suited for organic compounds, films, surface residues, coatings, and polymers analyzed using a Fourier Transform Infrared Spectrometer.

- Sampling Modes: ATR (ATR FTIR spectroscopy), specular reflectance, absorbance reflectance, and transmission.

- Spectral Range: Ranging from 4000 to 450 cm⁻¹ (Mid‑IR) and 7000 to 4000 cm⁻¹ (Near‑IR).

- Resolution: <0.09 cm⁻¹ with wavenumber accuracy better than 0.005 cm⁻¹.

- Wavenumber Accuracy: ±0.005 cm⁻¹.

- Microscopy Support: Spot identification and spatial mapping with 15× and 35× magnification.

What Is the Difference Between IR and FTIR?

Infrared spectroscopy (IR) refers to a general class of spectroscopy using infrared light. Fourier Transform Infrared Spectroscopy specifically involves an interferometer and a Fourier Transform to produce high‑resolution spectra.

In fact, nearly all modern IR spectrometers are Fourier Transform Infrared Spectrometers.

What Is the Difference Between FTIR and Raman Spectroscopy?

Both FTIR and Raman spectroscopy reveal molecular insights. FTIR spectroscopy is more effective for polar bonds like O‑H, C=O, and N‑H, whereas Raman is ideal for non‑polar bonds like C–C, C=C, and S–S.

Strengths

FTIR is designed for efficient and reliable compound identification, ideal for complex organic materials, polymers, and coatings. It offers:

- Access to rich spectral libraries for confident compound classification.

- Chemical mapping capabilities for analyzing small sample regions.

Limitations

FTIR is versatile and can be applied to any identification, but it is limited to certain diagnostic powers, which depend on contextual interpretation and, mainly, sample selection.

- A reference or standard sample is often required for spectral comparison.

- Many inorganic compounds like carbonates reveal overlapping peaks, resulting in blurry spectral specificity.

- Reflection and transmission modes demand thin samples for the IR light to penetrate or reach a reflective surface.

- Opaque or strongly IR-absorbing materials typically fall outside the usable range for these modes.

- The microscopes at Covalent are limited to a stage height of approximately 20 mm, restricting analysis of some larger samples.

Unsure Whether FTIR Is Right for You?

Learn more about Fourier Transform Infrared Spectroscopy testing services today.

Sample Information

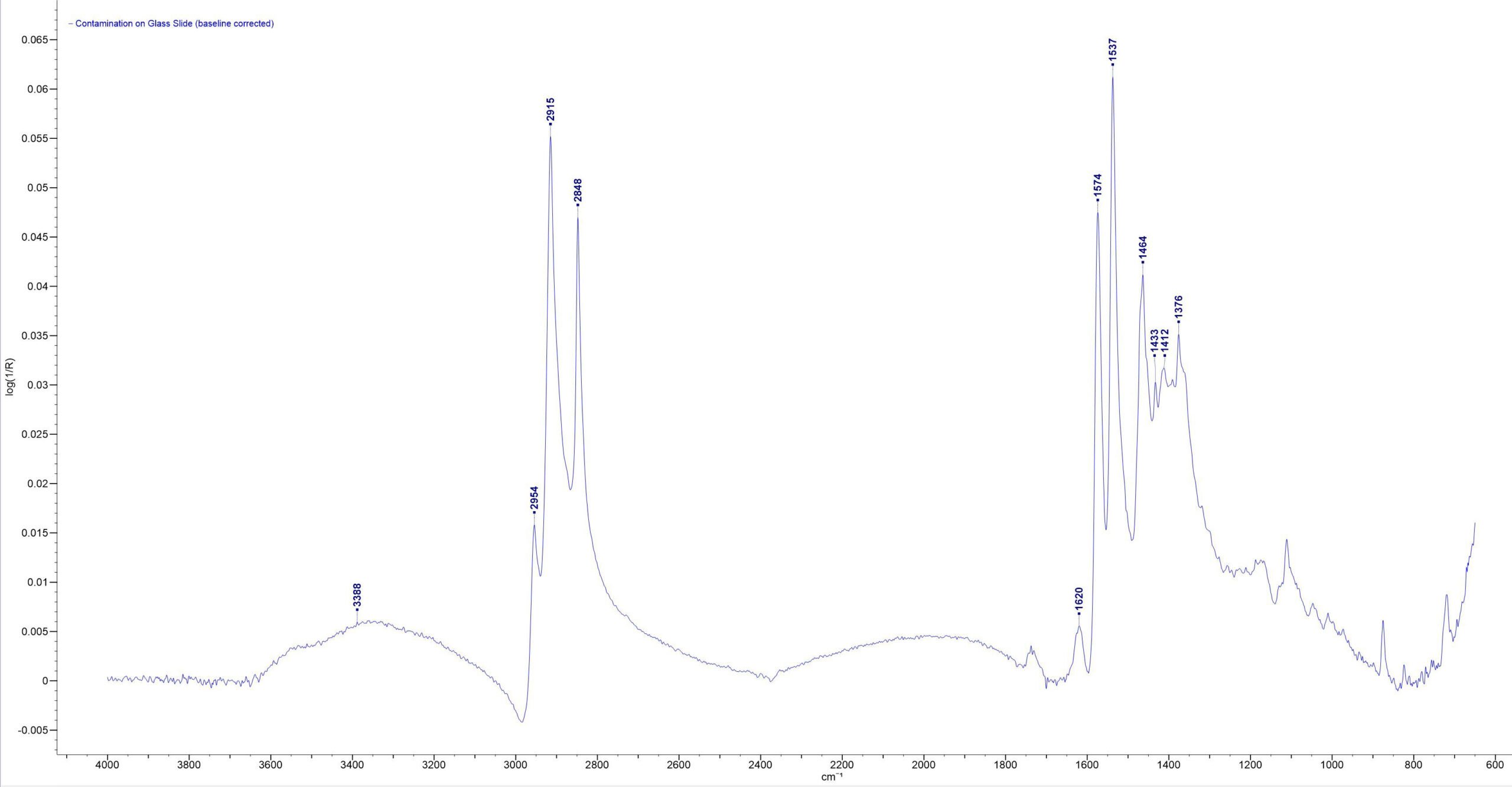

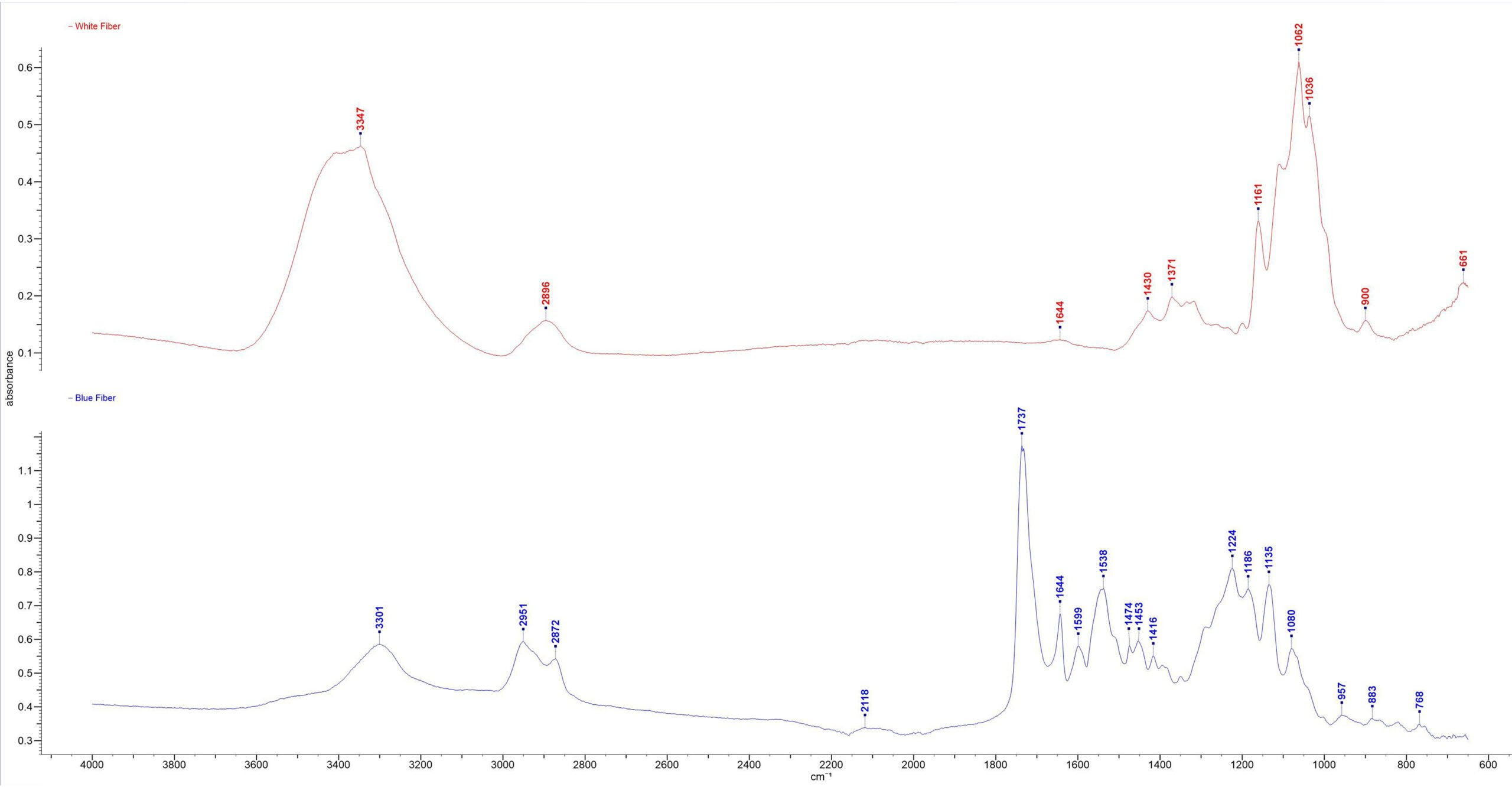

The graph (spectrum) from an IR spectrometer displays transmittance or absorbance intensities across the different inverse wavelengths, which is the key to accurately identifying molecular bonds and chemical structures.

- Covalent’s spectra library enables fast classification and spectra matches.

- Peak positions and intensities reveal qualitative analysis of compound concentration.

- Surface-level insights can be analyzed for coatings, residues, or layered materials using the ATR mode.

Our FTIR reporting helps answer all chemical-level questions, from solving a failure to validating a formulation to tracking material degradation.

Reflection mode FTIR – Contamination on a Glass Slide – Ca Stearate: Contamination found on a reflective surface identified as calcium stearate.

What we accept:

Each technique, transmission, reflection, or ATR, has its own sample requirements to achieve a clean, accurate spectrum:

- For transmission mode, the optimal film thickness should ideally be under 10 µm.

- Flat surfaces are ideal for obtaining the highest data accuracy and quality in both transmission and reflection modes.

- Covalent’s FTIR system, with a vertical stage clearance of up to 20 mm, accommodates sample sizes between ~150 µm and 10 µm.

- All physical forms, solids and liquids, are accepted, provided they are compatible with infrared exposure.

Our scientists will guide you with tailored prep protocols to ensure maximum data quality.

Use Cases

Electronics & Semiconductor

FTIR analysis detects unknown residues on PCBs and other electronic components, helping ensure product reliability. It verifies polymer coatings and encapsulants, and enables comparison of raw materials across production cycles to maintain consistency and quality.

Energy & Batteries

The technique identifies chemical degradation in electrodes caused by electrolyte exposure, helping optimize battery performance. It also detects cross-linking or oxidation in battery polymers and validates material formulations for reliable energy storage components.

Industrial Manufacturing & Materials Science

FTIR reveals thin contamination films on metal tooling, pins, and plates, supporting process quality control. It confirms polymer compositions, evaluates coatings and films, and analyzes surface residues for failure investigations.

Consumer Goods & Polymers

FTIR verifies raw material authenticity using molecular fingerprinting and helps investigate degradation or aging in polymers and coatings. It also detects contaminants in packaging materials, films, or fibers, ensuring product safety and consistency.

Research & Development

FTIR provides rapid, non-destructive molecular fingerprinting of solids and liquids. It characterizes functional groups and chemical bonds in novel materials, and integrates seamlessly with Raman, SEM-EDS, XPS, and GC-MS for comprehensive material analysis.

Complementary Techniques

FTIR is an initial screening method that opens the door for advanced structural and trace-level analysis. Usually, it is paired with various complementary techniques that expand analytical reach into inorganic, elemental, and trace-level domains.

The commonly paired methods include:

- GC-MS (Gas Chromatography–Mass Spectrometry): Best-fit for identifying volatile organics and trace additives that may not be captured in FTIR spectra.

- NMR Spectroscopy: Effective in resolving molecular structures and quantifying components in complex mixtures.

- Raman Spectroscopy: Effective for identifying molecular structures and crystal forms that are weak or inactive in FTIR spectra.

- SEM-EDS (Scanning Electron Microscopy with Energy-Dispersive X-ray Spectroscopy): Tailor-made for metals and inorganics, SEM-EDS delivers high-resolution imaging and elemental analysis.

- XPS (X-ray Photoelectron Spectroscopy): Analyzes surface-sensitive chemical composition and oxidation states of elements.

FTIR is often the first test in a multi-technique strategy, guiding deeper analysis.

Gas Chromatography-Mass Spectrometry (GC-MS)

Identifies and quantifies small organic molecules in mixtures. Explore

Nuclear Magnetic Resonance Spectroscopy (NMR)

Determines molecular structure, composition, and dynamics. Explore

Raman Spectroscopy

Measures inelastic photon scattering for chemical identification. Explore

X-ray Photoelectron Spectroscopy (XPS)

Measures surface elemental composition and chemical states. Explore

Why Choose Covalent for Your FTIR Needs?

We empower our clients with enterprise-grade insight, thanks to our scientists' multidisciplinary expertise in materials science, polymer chemistry, and surface engineering.

Every test is given personalized and undivided attention, from technique selection to spectral interpretation, to ensure high-value outcomes.

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

When is it appropriate to use transmittance vs. absorbance?

It mostly depends on what information you want to see. Absorbance is usually chosen because it makes peaks and peak heights clearer, and it follows Beer’s Law for direct correlation with concentration. Transmission is the historical way FTIR spectra were collected, so older libraries often match better with transmission data. The log scale of transmission can also make smaller peaks and valleys easier to notice.

What can FTIR analysis be used for?

FTIR analysis is most often used to quickly identify polymers and organic molecules, making it a fast and reliable tool for confirming material composition.

What is the importance of the wavenumber in FTIR analysis?

Wavenumbers are the direct output of an FTIR interferogram. Each functional group corresponds to a narrow wavenumber range. Recognizing a peak at a given position helps identify the structural groups present in the sample.

What are the differences among FTIR, Micro-FTIR, and Nano-FTIR?

FTIR measures bulk samples using transmission, reflection, or ATR. Micro‑FTIR works with a microscope to narrow the area below 150 µm. Nano‑FTIR couples Atomic Force Microscopy (AFM) with FTIR to map chemical features at the nanoscale.

What information can be obtained from an FTIR spectrum?

An FTIR spectrum shows the optical properties of a sample (like % transmittance) and identifies functional groups such as C=O, N‑H, and O‑H, making it possible to determine what bonds are present.

Are there different types of FTIR techniques?

There are multiple ways to prepare samples to produce the best output but the final spectrum will always look the same with x-axis of wavenumber and y axis of % transmittance or absorbance. The different accessories for collecting FTIR data we have at Covalent are diamond and germanium ATR crystals, transmission, reflection as well as micro-germanium ATR, micro-transmission and micro-reflection.

Can FTIR be used for quantitative analysis?

Yes, but under defined conditions. A calibration curve of known concentrations is needed. The unknown sample is then compared against this curve, allowing FTIR to be used quantitatively as well as qualitatively.