What Is Gas Pycnometry?

Gas Pycnometry (or just pycnometry) is a high-resolution analytical technique used to measure the true volume and density (also called pycnometric or skeletal volume/density) of solids and semisolids, using the principles of gas displacement. These measurements are performed with a gas pycnometer, which can use various inert gases, although helium is the most common; hence, you may also hear of helium pycnometers or helium gas pycnometers.

True Density

Measurement

Precisely determines the pycnometric density of solids and semisolids.

Porosity Insight

Reveals voids and closed pores by comparing true vs. bulk density.

Quality Control

Ensures consistency across batches, materials, and processes.

Why Use Gas Pycnometry?

Gas pycnometers provide a fast, non-destructive, and repeatable way to deliver high-resolution volume and density measurements for various materials, regardless of shape or form.

A benefit of the gas displacement technique is that it allows for very sensitive measurements, with a density resolution of 0.0001 g/cm³. Identifying the true density of a material provides valuable information on its pores and voids, which is useful when comparing with the bulk densities of porous materials.

As a result, gas pycnometry is a rapid and cost-effective quality control technique across multiple industries.

Versatile Across Materials

Accurately measures metals, ceramics, polymers, powders, films, and composites.

Powder and Solid Flexibility

Works seamlessly with fine powders, rigid solids, and irregular shapes.

Non-Destructive Testing

Preserves sample integrity while delivering high-resolution density data.

Working Principle

Gas pycnometry works on the principles of Archimedes’ Fluid Displacement and Boyle’s Gas Expansion to analyze the true volume and density of solid and semisolid materials.

The first step measures the sample’s mass using a sensitive analytical balance. The sample of known mass is then placed in a sample chamber of predetermined volume, which is then sealed and pressurized typically to a target 18 psi, using inert gas such as Helium or Nitrogen. Once the gas fills the space around the sample, including any accessible pores, the pressure stabilizes. A valve connecting the sample chamber to a calibrated internal reference chamber is then opened, allowing gas to flow between the sample and reference chambers, resulting in a pressure differential proportional to the sample volume.

For some samples, such as fine powders, this process is reversed to prevent the displacement of fine particles.

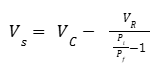

The pressure readings before and after this equilibration process are then used in the following equation to determine the true volume of the sample:

In the above equation, VS is the true volume of the sample, VC is the volume of the sample chamber, VR is the volume of the reference chamber, and Pi and Pf are the initial and final pressures, respectively.

The integrated software then calculates the true density from simply the ratio of the sample mass to the averaged true volume from a series of repeated pycnometry measurements. Specific gravity can also be easily obtained by a simple ratio of the true density to the density of water at the regulated analysis temperature.

Equipment Used for Gas Pycnometry:

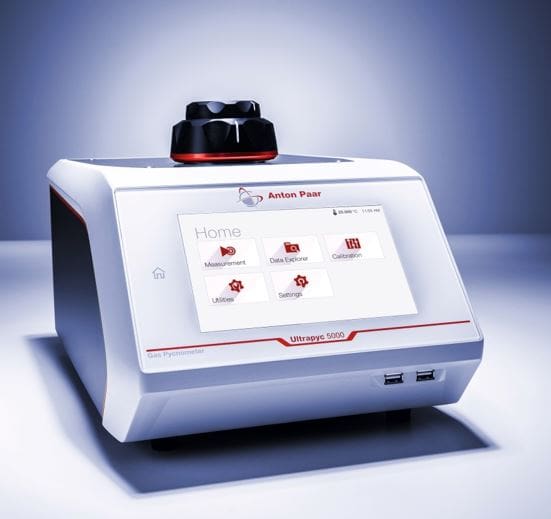

Anton Paar Ultrapyc 5000 Micro Gas Pycnometer

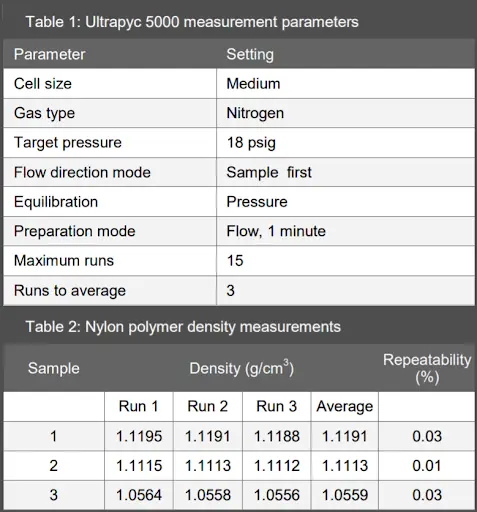

At Covalent, we use the market-leading Anton Paar Ultrapyc 5000 Micro gas pycnometer, optimized for measuring small sample quantities.

Cell Options:

- Micro (4.5 cm³): Accuracy 0.10% | Repeatability 0.05%.

- Meso 1.8 cm³): Accuracy 0.30% | Repeatability 0.15%.

- Nano (0.25 cm³): Accuracy 1.00% | Repeatability 0.50%.

Additional Features:

- Preparation modes: Flow, Pulse, or Vacuum.

- Pressure resolution 0.001 psi.

- Transducer accuracy: Better than 0.1 %.

- Temperature control: 3 – 50°C with stability better than ± 0.05°C.

Key Differentiators

- True volume, true density, specific gravity, and porosity measurement for solids and semisolids.

- Accuracy of 0.10–1.00%, depending on the cell used.

- Repeatability of 0.05–0.50, depending on the cell used.

- PowderProtect mode for accurate measurement of fine powders.

- Temperature-controlled from 3–50℃, with stability better than ± 0.05°C.

Strengths

- Unmatched accuracy, reproducibility, and reliability for volumetric measurements.

- Fast repeated measurements in as little as 10 minutes per sample.

- Flexible analysis modes for a wide variety of sample types.

- Non-destructive.

- Ideal for hydrophobic or liquid-sensitive materials (no liquid-immersion needed).

- Tailored to measure the gas-accessible solid material, better representing the true material properties.

- Works well with very small sample amounts, so high-quality can still be obtained for quality assurance/quality control, even if you are sample-constrained.

Limitations

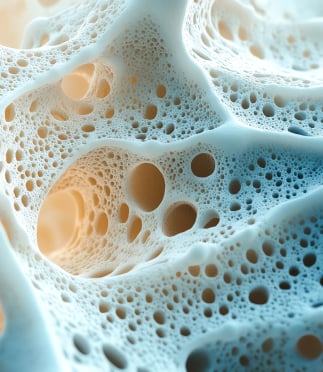

- Sensitive to closed porosity.

- Closed pores or voids are inaccessible to the analysis gas, meaning that the massless volume of these pores/voids will contribute to the measured true volume and impact the resulting density.

- Unsuited for measuring the density of liquids or suspensions.

- Does not identify or measure the size of any pores present.

Unsure Whether Gas Pycnometry Is Right for You?

Discover how accurate density and porosity data can guide better decisions.

Sample Information

The table above reports computed skeletal density for a commercially available nylon sample, produced from volume measurements taken from an Anton Paar Ultrapyc 5000 pycnometer. It has been previously demonstrated that increased nylon crystallinity correlates with increased skeletal density, which suggests that Sample 1 may be slightly more crystalline than the other nylon samples. This hypothesis was separately validated in another study.

What we accept:

- Samples must be solid or semisolid (Aerogels, pastes, gels, films, etc.).

- Sample size must be within 0.125cm3 up to 4.5cm3 (Larger samples can be prepared to meet these size requirements; measurements are most successful when samples occupy 50-75% of analysis cell volume).

- Samples must be non-volatile (mass and structure need to stay unchanged via gas adsorption or desorption; the test procedure can be adapted to volatile samples, if necessary).

Use Cases

Curing Studies

Track volume contraction and density increase of epoxy resins before and after UV curing to better understand curing efficiency.

Quality and Batch Control

Verify consistent densities across batches, lots, or sub-regions of uniform materials to ensure specifications and performance compliance.

Porosity Studies

Compare bulk and true densities to calculate porosity percentage, gaining insight into the extent of internal voids or closed pores.

Process Comparison and Validation

Differentiate material properties by comparing the density and porosity of hot-melt extruded plastics and injection-molded plastics, correlating to performance outcomes.

Environmental Applications

Analyze soil and mineral specific gravity or determine microplastic densities to support environmental assessments and regulatory testing.

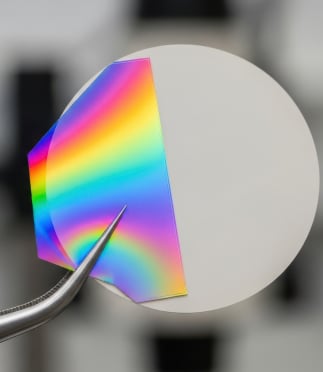

Thin Films

Evaluate thin film properties that often differ significantly from bulk materials but strongly influence performance in advanced applications.

Metals / Ceramics / Refractory Materials

Assess sintering quality, density, and porosity of precursors, intermediates, and final products to optimize material processing.

Pharmaceuticals

Aid quality control by measuring true density to ensure packability, flowability, and controlled dissolution of drug formulations.

Battery / Energy / Catalysts

Provide critical data on electrode design, membrane porosity, catalyst characterization, crystallinity, and overall component quality in energy storage and conversion systems.

Complementary Techniques

- Fourier Transform Infrared Spectroscopy (FTIR): Identify material composition, complementing pycnometry’s physical property data by providing chemical structure insight.

- Laser Diffraction: Relate particle size to density, providing key formulation parameters for materials such as battery components.

- Porosimetry: Measure pore size distribution and volume; complements pycnometry to calculate porosity percentage attributed to measurable pores.

- Scanning Electron Microscopy (SEM): Examine size, shape, and internal features at high resolution, especially with FIB cross-sectioning.

- Tap Density: Compare true density with bulk and tapped density to assess porosity, packing efficiency, compressibility, and flowability.

- X-ray Computed Tomography (Micro-CT): Visualize and measure internal pores or voids to complement pycnometry’s density and porosity insights.

Fourier Transform Infrared Spectroscopy (FTIR)

Rapid, non-destructive molecular fingerprinting across materials. Explore

Scanning Electron Microscopy (SEM)

Images surface topography and composition with electrons. Explore

X-ray Computed Tomography (Micro-CT)

Non-contact, non-destructive 2D/3D images at micron scale. Explore

Why Choose Covalent for Your Gas Pycnometry Needs?

At Covalent, we bring together technical expertise and world-class technology to obtain high-quality data and consistent results.

Our turnaround time for gas pycnometry projects is usually 1–3 days. We can also deliver a complete picture of your material’s density, porosity, composition, and performance with complementary analytical techniques.

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

Why is helium used as the displacement or analysis gas?

Helium is used due to being inert with most materials meaning it won’t react with or change the material in any way during the measurements. It also has a very small atomic size which allows it to penetrate very small micropores, giving the most accurate measurement of the solid sample’s true density.

Can pycnometry measure porosity?

Not directly. Gas pycnometry provides the true density, which is the density of the solid material, including the volume contributions from internal closed pores which the gas cannot access. However, the porosity % can be calculated if the bulk density, or the total pore volume are known or measured. We frequently calculate this parameter from complementary measurements performed in sequence.

Do samples need to be dry before measurement?

Typically, yes, since moisture or solvents are likely to be volatile and alter the measured volume and mass. However, we can configure the experiment to measure the volume or density change with respect to time to analyze these changes if you wish to study this volatility.

How are the instruments or measurements calibrated?

We perform sample and reference chamber calibrations as well as verification measurements on calibrated metallic spheres before every single project to ensure the instrument is running and tuned optimally for the analysis gas, sample cell, and sample materials used for your project.

How long do measurements take?

Once the instrument is calibrated and the samples are prepared and thermally equilibrated, we typically perform between 5-15 repeat measurements per sample to provide some statistics. This process, including a pre-treatment gas flow, takes typically between 15-25 minutes per sample.