What Is Mechanical Testing?

Mechanical testing evaluates how materials respond to mechanical or movement-related forces such as stress, strain, impact, and fatigue. These tests ensure that materials can withstand real-world conditions without failure. It measures a material’s strength, elasticity, flexibility, hardness, toughness, fatigue resistance, impact performance, and stability under both mechanical and thermal stress.

Why Invest in Mechanical Testing?

Mechanical testing helps understand a material’s properties and predicts its behavior in real-world conditions. This is important for failure prevention and informs future design decisions.

- Ensure device performance will function as intended.

- Ensure compliance with industry standards that often make reliable performance a legal or professional requirement, especially for items affecting safety or health.

- It helps minimize cost, as warranty claims and recalls are expensive. Failures of a structural or mechanical nature are usually broad-based, as they affect every item produced rather than being rare failures.

When Should Mechanical Testing Be Performed?

- Research and Development: Material selection, process and design improvement.

- Qualification: Ensure material quality meets performance specifications.

- Production: Monitoring consistency and Quality control.

- Failure Analysis: If a part fails in service due to cracking, warping, or deforming , mechanical testing helps narrow down whether the issue is material, process, design, or environment-related.

Industries That Use Mechanical Testing

Mechanical testing is used in various industries for its importance in understanding material function and behavior. Here are some industries that use mechanical testing:

Aerospace & Automotive

To test strength, fatigue, and impact testing for components that are exposed to tremendous forces when flying or driving.

Construction & Infrastructure

Evaluates the mechanical strength of building materials and performance under environmental strain and stress.

Consumer Products

Evaluates the durability and reliability of everyday items.

Energy & Batteries

Test structures under stress, specifically in power generation and battery applications, where there are moving components or connections operating in motion, such as an electric vehicle. Additionally, it looks at the functioning of a material when it is exposed to harsh environments.

Semiconductors & Electronics

Measures the strength of components, packaging, and connections. For example, testing if an iPhone will survive a fall.

Medical Devices & Biotechnology

Ensures fatigue and wear patterns for implantables like stents and valves that must function repeatedly for years inside a body, as well as joint replacements, synthetic bone graft strength, and more.

Key Differentiators

Advantages

- Instead of inferring properties from chemical or physical traits, testing a material by exposing it to real-world conditions or forces allows its performance to directly transfer from the lab to production.

- It is standardized and used in a variety of compliance applications that are concerned about performance. mechanical testing validates the sufficiency of the selected manufacturing process by focusing solely on results rather than methodology.

- It is versatile and can perform tests on anything from thin films to metals, whether it is large or small.

- It is quantitative and specific. Rather than interpreting and extrapolating results, it can provide specific ranges or probabilities of failure in various use conditions.

Limitations

- Testing, especially when going till failure, can be destructive to the sample.

- Reproducing physical conditions can be expensive and difficult. We may not always be able to reproduce specific environmental conditions in the lab.

- It is time-intensive, and long-term fatigue testing may require thousands of cycles to a specific condition over an extended period of time.

How Does Mechanical Testing Work?

Mechanical testing applies controlled stress — such as tension, compression, bending, or impact — to evaluate how a material deforms or fails. By observing changes in shape, strength, or elasticity, engineers determine whether the material will perform as expected under real or accelerated conditions.

Types of Structural and Mechanical Testing

- Tensile strength: Measures the maximum tensile stress a material can handle before breaking. It is used to test metals, polymers, composites, and thin films.

- Hardness Testing: Measures resistance to indentation, scratching, and surface deformation of metals, ceramics, coatings, and polymers.

- Fatigue resistance/fracture toughness: Measures a material’s durability under repeated stress and its ability to resist crack spreading. It is used in aerospace alloys, medical devices, structural composites, and automotive components.

- Creep behavior: Tests the deformation of a material under constant load and looks at its temperature over time.

- Impact resistance: Looks at a material’s ability to absorb impact from sudden shock.

- Scratch or wear resistance: Measure a material’s resistance against abrasion, surface scratching, or long-term wear. It is most commonly used in coatings, thin films, plastics, and metal surfaces subject to friction.

How Results Are Tracked and Reported

At Covalent, we support the project from the first email. We will help you choose the right method, advise on the best way to ship the samples, and discuss the scope of work with you. In some cases, you can request a live session in the lab or remotely. Our reports include:

- High-resolution images, spectra, tables, and figures.

- Quantified measurements with precision calibration, if required.

- Raw data upon request.

- Interpretation aligned to goals.

- Information about used equipment and methods.

Our engineers will be happy to follow up on any questions or concerns you may have.

Why Choose Covalent for Mechanical testing Services?

Covalent is the answer for all mechanical testing needs. Our cutting-edge lab is fully equipped with comprehensive tools, allowing for deeper insight by combining data from multiple tests. Our expert and highly qualified team uses various methods to piece together the answers you need. We also offer live sessions where you can collaborate with our expert team, pinpoint your desired features, and select the right tools.

Frequently Asked Questions

What is the difference between tensile testing and hardness testing?

Tensile testing looks at the material’s behavior when pulled, while hardness testing measures the resistance to indentation or scratching. A material could fracture or shatter when pulled but be very resistant to scratching, or vice versa. For example, silly putty would pull wonderfully but indent easily with any contact, compared to a ball bearing, which might resist scratching and pulling.

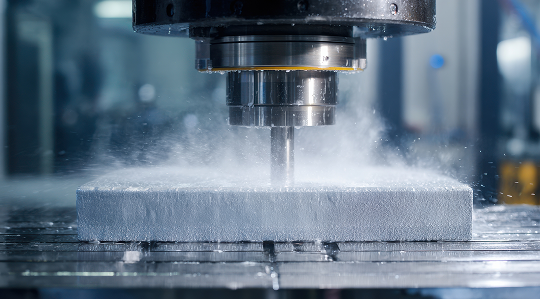

Do you provide machining services to prepare standard test specimens from our parts?

Yes, Covalent can help with sample preparations, including machining services to separate specimens from larger parts.

Are mechanical tests like fatigue and tensile testing destructive to the sample?

Yes, many tests are destructive, particularly when testing to failure.

Is your laboratory Nadcap or ISO 17025 accredited for mechanical testing?

Covalent is accredited to ISO/IEC 17025 for more than 60 Standardized and Covalent-developed analytical methods, as listed in our scope of accreditation. Covalent is not Nadcap accredited currently.

Can you perform mechanical tests at elevated or cryogenic temperatures?

Yes. Our lab can conduct mechanical tests at elevated or cryogenic temperatures.

Can you test exotic alloys or additive-manufactured metal samples?

Yes, we can test both, test exotic alloys and additive-manufactured metal.

What is the minimum sample size required for tensile or fatigue testing?

Sample sizes are determined by the specific test used. For example, dogbone geometries are widely used in tensile testing. Contact a Covalent material scientist to understand what properties you are evaluating, and to discuss equipment compatibility and sample preparation requirements.

Do you offer accelerated aging or high-temperature mechanical testing?

Yes, we offer accelerated aging or high-temperature mechanical testing.

Related Techniques for Mechanical Testing

- CFP (Compression or Flexural Property Testing): Assesses mechanical strength and stiffness under compression or bending loads.

- DMA (Dynamic Mechanical Analysis): Measures viscoelastic properties such as modulus and damping behavior across different temperatures and frequencies.

- Mechanical X-Section (Cross-Sectioning): Analyzes layer thickness, defects, and interface integrity in multilayer structures.

- Micro-CT (Micro–Computed Tomography): Offers 3D internal structure analysis for detecting defects, porosity, and geometric features.

- Nanoindentation: Evaluates hardness and elastic modulus at the nanoscale, revealing the mechanical properties of thin films and surfaces.

- SAM (Scanning Acoustic Microscopy): Inspects internal structures and detects defects like delamination or voids using acoustic waves.

- Scratch Test (Nano-Scratch): Tests the scratch resistance and adhesion strength of coatings and thin films.

- Tensile Testing: Measures tensile strength, elongation, and Young’s modulus of materials.

Dynamic Mechanical Analysis (DMA)

Characterizes thermal and mechanical properties of soft materials. Explore

Mechanical Cross-Section Analysis (X-Section)

Uncovers microstructures and defects causing performance issues. Explore

Scanning Acoustic Microscopy (SAM)

Locates internal flaws like cracks, voids, and delamination. Explore

X-ray Computed Tomography (Micro-CT)

Non-contact, non-destructive 2D/3D images at micron scale. Explore