What Is Digital Optical Microscopy?

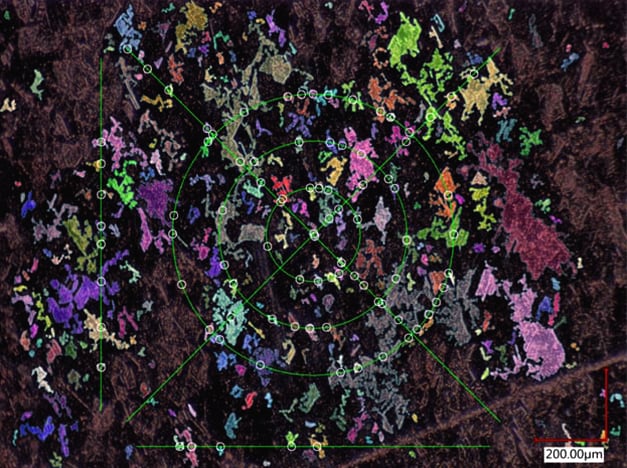

Digital optical microscopy uses advanced optical microscopes to generate images like modern digital cameras, capturing the light reflected from or transmitted through a sample under set illumination. However, unlike a simple camera, modern optical microscopes also include intrinsic lens systems and sophisticated illumination systems that facilitate high magnification and dynamic range images with micron-scale resolution. Applications include imaging and measuring critical dimensions, defect features, solder connections, and cross-sectioned parts in the semiconductor, materials science, and precision manufacturing industries.

Performance

Accurate, high‑resolution, automated measurement and analysis.

Advanced Imaging

Wide depth of field, flexible lighting, and tilt for detailed surface imaging.

Analytical Support

Full‑service microscopy, profilometry, and failure analysis tools.

Why Use Digital Optical Microscopy?

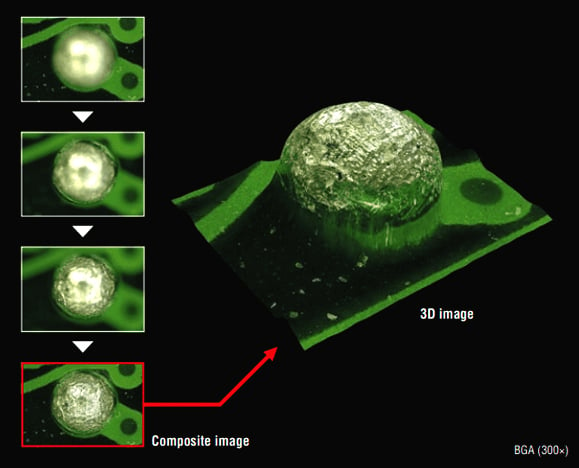

Our 3D optical microscopy services use extended depth-of-field optics with automated compositing and image stitching to integrate images captured across multiple focal planes and large areas. This produces fully focused, high-resolution images across the entire field of view, even with significant height variations. A high-precision automation system provides precise control over different illumination modes for optimal imaging quality.

Versatile Illumination

Accommodates multiple lighting techniques to reveal surface features.

Depth-of-Field Imaging

Generates 3D renderings of surfaces or combines multiple focal planes into a single, fully in-focus 2D image.

Large-Area Image Stitching

Captures large regions of interest at high resolution by seamlessly combining multiple images.

Working Principle

Digital Optical Microscopy captures high-resolution images using advanced lenses and controlled illumination. Automated depth-of-field compositing and image stitching generate entirely focused images on complex surfaces. Adjustable lighting and tilting ensure precise edge definition and accurate dimension measurements.

Equipment Used for Digital Optical Microscopy:

Keyence VHX-X1

- Dynamic Microscope Tilt Range: -89° to +89° from vertical.

- Magnification Range: 20x to 6000x.

- Maximum Field of View 15.24 mm (lateral) x 11.40 mm (vertical) at 20x magnification.

- Illumination Modes: customizable bright-field, dark-field, and mixed lighting.

- High-precision, automated, in-situ dimensional analysis.

- High-quality depth composition imaging.

Keyence VHX-6000

- Dynamic Microscope Tilt Range: −60° to 90° from vertical.

- Magnification Range: 20× to 2000×.

- Maximum Field of View: 15.24 mm (lateral) × 11.40 mm (vertical) at 20×.

- Illumination Modes: Customizable bright‑field, dark‑field, and mixed lighting.

- Capabilities: High‑precision, automated, in‑situ dimensional analysis.

Key Differentiators

Our optical microscopy systems can tilt the microscope relative to the sample and image with a high depth of field to enhance edge definition and improve feature visibility on complex geometries.

Strengths

- High-resolution and accurate imaging.

- Reproducible images with multi‑modal illumination and extended depth of field.

- Widest possible depth-of-field (without cross-sectioning) among direct imaging/microscopy techniques.

Limitations

- It does not have as high a spatial resolution as other scanning probe microscopy methods, such as AFM.

- It may be less efficient when more precise 3D-height measurements are needed.

- Covalent’s other techniques may be a better fit in certain cases.

Unsure Whether Digital Optical Microscopy Is Right for You?

Covalent's expert team is ready to help understand your requirements and testing needs to offer the ideal solution.

Sample Information

What we accept:

We accept solid and liquid samples (liquids must be in sealed containers). The maximum sample mass is 5 kg. The maximum solid dimensions are 100 mm (L) × 100 mm (W) × 40 mm (T). For larger parts, we can separate and/or cross‑section components to expose the features of interest.

Use Cases

Semiconductor & Electronics

Digital optical microscopy is used to inspect ICs, wafers, PCBs, and advanced packaging for defects, delamination, and grain structure. It enables non-destructive failure analysis, precise surface imaging, and dimensional verification of microfeatures.

Materials & Manufacturing

Supports dimensional inspection, surface quality assessment, and defect detection in machined or fabricated parts. Ideal for verifying tolerances and identifying imperfections in precision components.

Mechanical Testing & Research

Used to examine crack propagation, indentation patterns, and deformation zones after mechanical or thermal stress testing, offering visual correlation with material behavior.

Polymers & Coatings

Captures surface texture, layer uniformity, and microstructural defects in coatings, thin films, and polymer components to ensure quality and consistency during processing.

Medical Devices & Packaging

Evaluates bonding, sealing, and surface finish in medical assemblies and packaging, ensuring integrity and compliance under strict manufacturing standards.

Complementary Techniques

- 2D-X-ray or Micro-CT: Subsurface inspection to complement surface imaging.

- Atomic Force Microscopy (AFM) or Electron Microscopy: Nanoscale surface and sub‑micron feature imaging.

- Laser Confocal Scanning Microscopy (LCSM) or White Light Interferometry (WLI): High‑precision 3D height measurements of small features.

- Structured Light Profilometry: 3D height measurement of taller features over larger areas.

Atomic Force Microscopy (AFM)

Maps nanoscale topography and material properties with a sharp probe. Explore

Laser Scanning Confocal Microscopy (LSCM)

Non-destructive 3D imaging of sample surfaces. Explore

Structured Light Profilometry

Creates precise 3D models without contact or damage. Explore

White Light Interferometry (WLI)

Measures surface topography with sub-nanometer vertical resolution. Explore

X-ray Computed Tomography (Micro-CT)

Non-contact, non-destructive 2D/3D images at micron scale. Explore

Why Choose Covalent for Your Digital Optical Microscopy Needs?

Optical microscopy is fast, affordable, and effective, but at Covalent, it’s elevated through advanced digital systems and a broad suite of complementary tools. Our experts combine optical, confocal, WLI, SEM, and AFM methods to deliver focused, high-resolution views and actionable measurements for defect, dimensional, and microstructure analysis. For urgent or complex projects, we offer rapid turnarounds and live, guided sessions with our engineers.

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

What is the largest sample area you can measure with 3D optical microscopy?

Our digital microscope analysis can measure a 315 mm x 315 mm area in a single scan.

How small a feature can Digital Optical Microscopy examine?

In our optical microscopy lab, we can measure features at 2500x magnification. The field of view narrows to approximately 120 × 90 μm, allowing for imaging features that approach a micron in size.

Do you offer sample prep and cross-sectioning services?

Yes. In addition to our optical microscopy lab, we have a failure analysis (FA) lab with cross-sectioning capabilities so that we can get a complete look at your part.

Is the optical microscopy lab a good fit for my needs?

Reach out to us and let’s discuss. Tell us a bit about your sample and what you are trying to learn, and we can provide a free consultation for your digital microscope analysis needs and prescribe the right mix of measurements to get you the answers you need.