What Is Rutherford Backscattering Spectrometry (RBS)?

Rutherford Backscattering Spectrometry (RBS) is a quantitative ion beam technique for measuring composition, thickness, and depth in materials, especially thin films and multilayer structures.

A collimated beam of high-energy helium (alpha particles) or hydrogen ions (protons) is directed at the sample. Upon elastic collisions with nuclei, a portion of the ions scatter backward. The energy retained by these ions depends on the mass of the atom they hit and the depth at which the collision occurred.

Heavier atoms yield higher-energy peaks. The resulting energy spectrum is depth-resolved, element-specific, and doesn’t require external standards. This makes RBS especially suited for stoichiometry validation, contamination profiling, and thickness measurements across multilayer stacks.

At Covalent, we extend RBS with Micro-RBS for micron-level spatial resolution and NRA/PIGE for light-element detection. Whether you’re mapping interfaces or assessing film uniformity on wafers, we configure RBS to deliver outcome-ready results.

Non‑Destructive Depth Profiling

Provides quantitative, layer‑by‑layer information without altering or damaging the sample.

Calibration‑Free Quantification

Direct analysis with no need for external standards, enabling accurate stoichiometry validation and contamination studies.

High Sensitivity for

Heavy Elements

Detects ppm‑level concentrations near the surface and resolves heavy‑element distributions with precision.

Why Use RBS?

When precise, non‑destructive depth profiling and stoichiometry matter, Rutherford Backscattering Spectrometry delivers calibrated, layer‑by‑layer insight. RBS is especially powerful for thin films and multilayer systems, offering ppm‑level heavy element sensitivity, accurate thickness validation, and contamination analysis without external standards.

Analytical Depth

Penetrates several micrometers into materials, enabling multilayer thickness profiling and buried interface detection.

Material Versatility

Effective on thin films, multilayers, crystalline substrates, and semiconductor wafers; extendable with Micro‑RBS and NRA/PIGE for light elements.

Integration Power

Pairs seamlessly with techniques like SIMS, XPS, TEM, ERDA, and XRF/PIXE to deliver full‑spectrum compositional and structural insight.

Working Principle

RBS operates on the principle of elastic nuclear collisions. High-energy ions, typically in the MeV range, are accelerated and directed toward a solid target. When these ions collide with nuclei in the sample, some are deflected backward and captured by detectors.

The amount of energy retained depends on two variables: the mass of the atom and the depth of the collision. This relationship allows a single spectrum to encode both composition and depth information, which can then be compared to simulated models to determine the thickness and composition of each layer in the material.

Key Differentiators

Covalent’s Rutherford Backscattering Spectrometry platform offers high-precision, layer-by-layer insights across a wide range of advanced materials.

| Parameter | Specification |

|---|---|

| Analytical Depth | Up to several micrometers, depending on energy and material density, with buried-layer resolution |

| Material Compatibility | Most solids; ideal for thin films on substrates or multilayered stacks |

| Spatial Resolution | Millimeter scale; micron-level with Micro-RBS |

| Depth Profiling | Quantitative, non-destructive, multilayer-resolved |

| Sensitivity | 0.1–1%; ppm-level near-surface for heavy elements |

Strengths

When non-destructive depth profiling and stoichiometry are critical, RBS is often the method of choice. Here’s what sets Rutherford Backscattering Spectrometry apart:

- High‑resolution, non‑destructive analysis of multilayer films.

- Ppm‑level near‑surface sensitivity for heavy elements (Z ≥ 20).

- Accurate, calibration‑free stoichiometry and thickness profiling.

- Ideal for thin film contamination studies.

- Provides deeper reach than surface‑sensitive methods like SEM, XRF, or XPS.

Limitations

RBS is powerful, but like any technique, it has limits. Covalent helps mitigate these through complementary methods and smart configuration.

- Lower surface sensitivity compared to techniques like XPS.

- Limited detection of light elements unless paired with NRA, PIGE, or ERDA.

- Results reported as areal density (atoms/cm²), requiring interpretation or calculation of film thickness with known or measured density (ex. with XRR).

- Energy resolution limits may blur signals from closely spaced heavier elements.

- Not suitable for volatile or vacuum-incompatible materials.

Sample Information

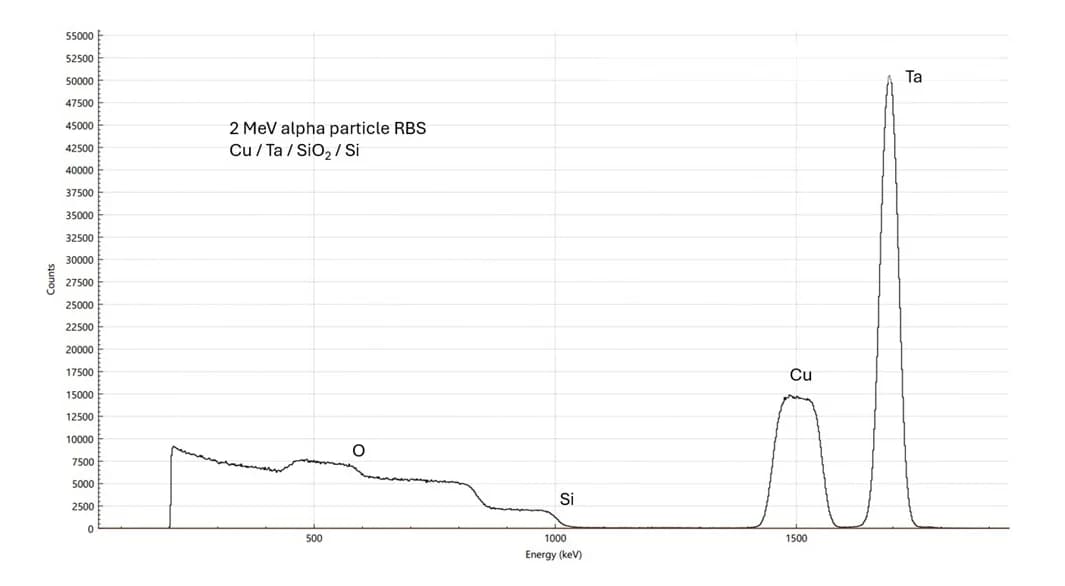

This is what a typical RBS output looks like, with different features corresponding to the various layers in the stack. In the above example, you can see:

- Oxygen (O) and silicon (Si) signals from the SiO₂ layer and the Si substrate.

- A distinct copper (Cu) peak from the top metallic layer.

- A sharp tantalum (Ta) peak from the barrier layer beneath.

Such outputs are used to visualize and confirm the elemental composition and arrangement of different layers in thin film structures.

What we accept

RBS requires stable, vacuum-compatible samples to ensure high-quality data capture. Our team evaluates all submissions before analysis and provides guidance for optimal preparation.

- Form: Flat, solid surfaces (thin films, multilayers, crystalline samples).

- Stability: Must tolerate vacuum and moderate ion exposure.

- Surface: Smooth, mechanically stable.

Use Cases

RBS is a go-to method across industries that demand non-destructive, high-resolution elemental depth analysis. Typical use cases include:

Semiconductor Manufacturing

Provides precise measurements of film thickness, dopant concentrations, and layer uniformity on wafers and other semiconductor devices.

Thin-Film Analysis

Accurately determines the composition, stoichiometry, and depth profiles for coatings ranging from nanometer to micrometer-scale, supporting applications in optics, photovoltaics, and electronics.

Materials Science Research

Researchers use RBS to study diffusion, corrosion, and interfacial reactions in advanced materials and multilayer structures.

Complementary Techniques

To extract full-spectrum insight from complex material systems, we frequently pair RBS with:

- ERDA (Elastic Recoil Detection Analysis): Suited for depth-resolved hydrogen and lithium profiling.

- NRA (Nuclear Reaction Analysis): Improves detection of light elements like hydrogen, nitrogen, and lithium.

- SIMS (Secondary Ion Mass Spectrometry): Delivers ultra-trace elemental sensitivity.

- TEM (Transmission Electron Microscopy): Visualizes atomic-scale structural interfaces.

- XRF (X-ray Fluorescence) or PIXE (Particle-induced X-ray Emission): Provides rapid, bulk compositional screening. Helpful to resolve possible peak overlaps in RBS spectra.

- XPS (X-ray Photoelectron Spectroscopy): Analyzes surface chemistry and bonding states.

Each method adds a layer of insight. Together with RBS, they enable full-spectrum characterization.

Transmission Electron Microscopy (TEM)

Images atomic structure, defects, interfaces with sub-nm resolution. Explore

X-ray Photoelectron Spectroscopy (XPS)

Measures surface elemental composition and chemical states. Explore

Why Choose Covalent for Your RBS Needs?

Our RBS workflows are engineered for rapid, reliable insights. With glovebox‑compatible systems, micron‑level beam control, and calibrated modeling, we address critical questions around depth, density, and material performance.

Every RBS dataset is processed using SIMNRA or JABS. Whether you’re qualifying a thin film, investigating a buried interface, or resolving a defect layer, we align ion beam outputs with your performance metrics.

Our experts optimize every configuration, anticipate tradeoffs, and interpret findings in the context of your device and process. This is how we deliver actionable material insight, not just raw spectra.

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

What is Rutherford Backscattering Spectrometry (RBS), and how does it work?

RBS is a nondestructive analytical technique for determining elemental composition and depth profiles. It works by measuring the energy of ions scattered from a sample’s surface, which reveals how elements are distributed throughout the material.

What types of materials or samples are best suited for RBS analysis?

RBS works best for thin films, multilayer structures, semiconductors, and solid materials where elemental composition and layer thickness are critical.

How is Rutherford Backscattering Spectrometry (RBS) different from SIMS or XPS?

XPS is highly surface-sensitive and can be destructive for depth profiles, whereas RBS provides quantitative, nondestructive depth profiling with minimal sample preparation. SIMS can detect impurities at very low levels, but it requires matrix-matched standards and is less reliable for major element stoichiometry compared to RBS.

When should I use Micro-RBS instead of standard RBS?

Micro-RBS is the ideal choice when spatially resolved elemental mapping is required. It enables localized analysis of microstructured samples or patterned devices.