What Is Cross-Sectional Analysis

(X-Section)?

Cross-sectional analysis is an analysis technique for quality control and failure analysis. When combined with tools like optical microscopy (OM), electron microscopy (EM), and energy dispersive X-ray spectroscopy (EDS), it examines material microstructures, characterizes critical defects, and develops strategic solutions.

With state-of-the-art processes and equipment, our engineers and technicians are able to cross-section features as small as 10 microns and develop methodologies for mechanical cross-sectioning of many different kinds of products.

Sample sectioning: Covalent offers sectioning capabilities for isolating regions of interest using tools like diamond wire saws, suitable for polymers, metals, glasses, and ceramics.

Grinding: Our laboratory offers various grinding media, including SiC grinding paper, diamond lapping paper, and resin-bonded discs, for preparing cross-sections from any material.

Polishing: We use alumina, colloidal silica, and polycrystalline diamond suspensions with polishing pads to produce scratch-free cross-sections. Vibratory polishing is available for samples needing minimal subsurface deformation.

Etching: We etch metals and alloys for grain structure analysis using chemical and plasma etching. Our chemists can produce custom etchants in-house if needed.

Other Details:

- Suitable for polymers, metals, glass, and ceramic materials.

- Sic grinding and diamond lapping paper, resin-bonded discs.

- Scratch-free cross-sections using diamond suspensions using polish pads.

- In-house custom etchants for metals and alloys.

High‑Resolution

Defect Insight

Reveals microstructures, layer thicknesses, cracks, voids, and interfacial defects that drive product failures.

Versatile Across

Materials

Compatible with metals, ceramics, polymers, composites, semiconductors, and multilayered structures.

Foundation for

Strategic Solutions

Combines precision sectioning with advanced microscopy (OM, SEM, EDS) to generate data that pinpoints root causes and guides innovation.

Why Use X-Section?

Cross-sectional analyses are key for characterizing the cause and effect of material defects or anomalies on the mechanical and chemical properties of components. They enable detailed analysis of the cause and location of defects, such as contamination at blind through interfaces in PCBs or determining crack morphology in stainless-steel pipeline welds.Cross sectional analysis gives a detailed look into product defects that could, or have, lead to premature failure. Cross-sectional analysis is used in industries including semiconductors, aerospace, biomedical, energy storage, and infrastructure.

- Provides physical, structural, and morphological information.

- Reveals layer thicknesses, interfacial features, voids, cracks, delamination, and manufacturing defects.

- Enables visual inspection and compositional analysis when coupled with microscopy techniques.

- Compatible with a wide range of materials, including:

- Metals.

- Ceramics.

- Polymers.

- Composites.

- Semiconductors.

- Can be used on multilayered or heterogeneous structures.

Failure Prevention & Reliability

Uncovers the hidden causes of defects that lead to premature product failure, enabling stronger, more reliable designs.

Actionable Quality Control

Provides detailed structural and compositional data that manufacturers use to validate processes and meet strict industry standards.

Cross‑Industry Relevance

Delivers critical insights across semiconductors, aerospace, biomedical, energy, and infrastructure, where performance and safety are non‑negotiable.

Working Principle

The sample is first mounted in resin or epoxy to stabilize the component of interest and then sectioned (cut) using a precision saw (e.g., diamond saw). Once cut, the sample is ground and polished in stages using abrasive pads and fine polishing agents. The final result is a flat, smooth cross-section and is examined to study internal structures, layers, interfaces, or defects.

Equipment Used for X-Section:

Diamond Wire Saw DWS.375E

- Vertical, endless diamond wire saw with max workpiece cutting area of 350 × 375 mm and max sample weight of 30 kg.

- Uses 3000 mm diamond wire loops (0.30 to 0.80 mm diameter) with continuously adjustable wire speed from 4 to 12 m/s for wet or dry cutting.

- Constant cutting pressure via gravity feed and industrial-grade drive/control technology for precise, robust operation.

- Color touch-panel control with multi-language interface (DE, EN, FR, ES, JP, CN) and integrated safety sensors for end-of-cut, open hood, and wire break detection.

AutoMet 300 Pro Grinder-Polisher

- 12″ [305 mm] platen and 2 hp [1500 W] base motor designed for demanding production lab environments and larger or multiple samples.

- Color touchscreen control with method creation/storage and Z-axis material removal by depth; supports manual or automated preparation.

- Platen speed 50 to 400 rpm (clockwise or counter-clockwise) with optional automated dispenser for cost savings and highly reproducible results.

- Integrated rinse and spin function, retractable water hose, and bowl liners for fast, simplified cleaning during grinding and polishing workflows.

Key Differentiators

Covalent’s cross‑sectional analysis stands out for its precision, consistency, and adaptability. It delivers clear views with minimal artifacts across even the most complex material systems.

Strengths

- Direct Visualization: Offers a clear, physical view of internal structures, layers, and defects.

- Cost-Effective: Equipment (saws, polishers) is generally less expensive compared to high-end techniques like FIB (Focused Ion Beam).

- Broad Material Compatibility: Suitable for metals, ceramics, polymers, composites, and semiconductor materials.

- Good for Layer Thickness Measurement: Enables accurate measurement of coatings, films, and multilayer stacks.

- Prepares Samples for Multiple Techniques: Cross-sections can be analyzed with optical microscopy, SEM, EDS, and other surface-sensitive techniques.

Limitations

- Destructive Technique: The process permanently alters or destroys the sample.

- Limited Depth Profiling Precision: Cannot provide continuous depth profiling like SIMS or AES; it only shows a snapshot at the sectioned plane.

- Risk of Sample Damage: Cutting or polishing may introduce artifacts like smearing, cracking, or delamination if not done carefully.

- Labor-Intensive Preparation: Requires multiple steps (mounting, cutting, grinding, polishing), which can be time-consuming.

- Resolution Limited by Analysis Method: While sectioning exposes features, the final detail depends on the resolution of the follow-up analysis (e.g., SEM vs. optical microscopy).

Unsure Whether X- Section Is Right for You?

Covalent’s expert team can help you determine a solution to your situation.

Sample Information

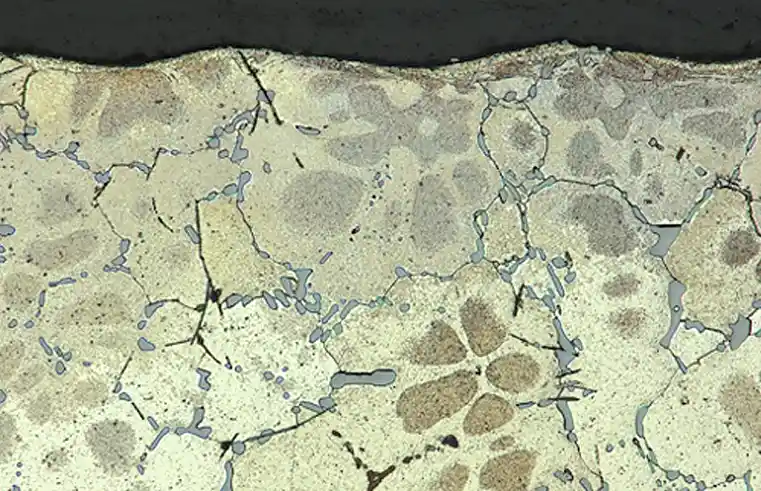

Optical micrograph of cast aluminum engine component (etched with Keller’s reagent) showing intergranular cracking. The intergranular cracking shown above is likely a result of thermal stress and degradation in extreme loading conditions. Advanced polishing methodologies, coupled with extensive metallurgical expertise, allows our engineers to find defects such as these cracks and determine possible causes based on environmental conditions during service. .

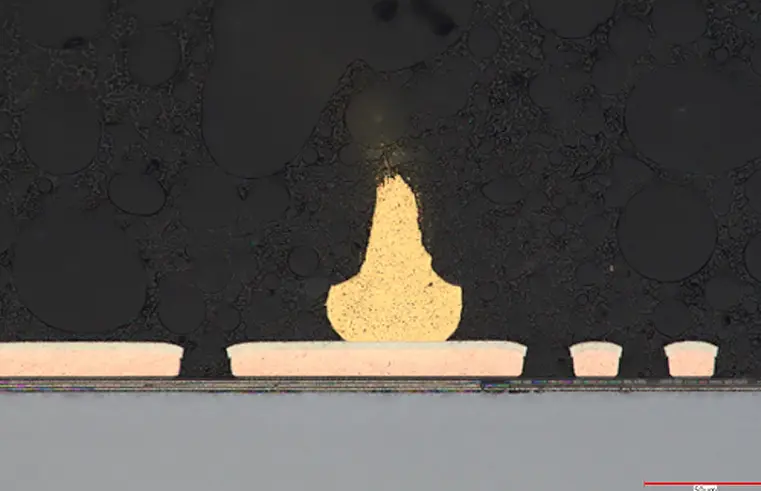

Optical micrograph of a gold wire bond on a silicon die in cross-section. Using advanced techniques our technicians and engineers are capable of cross-sectioning features as small at 10 microns with little to no polishing artifacts. This type of analysis can help determine the quality of gold wire bonds, helping to combat reliability issues in PCB components.

What we accept:

Size and Shape: Depending on the size and shape of the sample, samples may need trimming and custom fixturing to mechanically cross-section. Providing smaller samples will limit the amount of sample preparation time needed to perform this process.

Complementary Techniques

- Atomic Force Microscopy (AFM): Nanoscale surface topography and roughness analysis used to examine fine surface features of polished cross-sections, especially in semiconductors or MEMS.

- Electron Backscatter Diffraction (EBSD): Ultra-high-resolution imaging and analysis. Cross sections can be further thinned (via FIB) for atomic-scale analysis.

- Energy-Dispersive X-ray Spectroscopy (EDS or EDX): Elemental analysis at specific points or across layers in the cross-section that identifies materials, contamination, or compositional gradients.

- Fourier Transform Infrared Spectroscopy (FTIR) / Raman Spectroscopy: Molecular and chemical characterization identifies polymers, contamination, or specific chemical groups on exposed layers.

- Optical Microscopy (OM): For visual inspection of cross-sections at low to moderate magnification. Helps identify defects, layer structures, grain boundaries, and material contrasts after polishing.

- Scanning Electron Microscopy (SEM): High-resolution imaging of cross-sectioned surfaces that produce detailed morphological analysis, surface topography, fracture studies.

- Transmission Electron Microscopy (TEM): Ultra-high-resolution imaging and analysis. Cross sections can be further thinned (via FIB) for atomic-scale analysis.

- X-ray Microanalysis (e.g., Wavelength-Dispersive Spectroscopy – WDS): A more precise elemental analysis than EDS for when better spectral resolution and lower detection limits are needed post-sectioning.

- X-ray Computed Tomography (XCT or Micro-CT): 3D non-destructive imaging before sectioning to locate areas of interest or internal defects before deciding where to cut.

Atomic Force Microscopy (AFM)

Maps nanoscale topography and material properties with a sharp probe. Explore

Fourier Transform Infrared Spectroscopy (FTIR)

Rapid, non-destructive molecular fingerprinting across materials. Explore

Raman Spectroscopy

Measures inelastic photon scattering for chemical identification. Explore

Scanning Electron Microscopy (SEM)

Images surface topography and composition with electrons. Explore

Transmission Electron Microscopy (TEM)

Images atomic structure, defects, interfaces with sub-nm resolution. Explore

X-ray Computed Tomography (Micro-CT)

Non-contact, non-destructive 2D/3D images at micron scale. Explore

Why Choose Covalent for Your X-Section Needs?

Frequently Asked Questions

Identifying the right test can be complex, but it doesn’t have to be complicated.

Here are some questions we are frequently asked.

What are the three different types of cross-sections?

Mechanical cross-sections and FIB (focused ion beam) cross-sections are both types of cross-sections utilized for the same purpose but implemented by different means. Mechanical cross-sections are produced through physical removal of material, while FIB cross-sections utilize ion beams to remove material.

Why perform cross-sectional analysis?

Cross-sectioning can be performed in conjunction with other analytical techniques to verify the quality and failure of components throughout manufacturing and shipping.It is useful in analyzing features and defects in components across many industries.

What are the main applications and industries that use cross sectional analysis?

Cross-sections are used across engineering, from analyzing PCB components and internal circuits in tech, to validating corrosion resistance in biomedical implants, and assessing load-bearing reliability in construction and infrastructure.